Ukukhetha okuphelele kanyepassivation of insimbi engagqwali, ukususa amabala ahlukahlukene kawoyela, ukugqwala, isikhumba se-oxide, amalunga e-solder nokunye ukungcola.Ngemuva kokwelashwa, indawo engaphezulu imhlophe ngesiliva, ithuthukisa kakhulu ukumelana nokugqwala kwensimbi engagqwali, efanelekile izingxenye zensimbi engagqwali, amapuleti kanye nemishini.

Kulula ukuyisebenzisa, isebenziseka kalula, iyonga futhi iyasebenza, kanye nokwengezwa kwama-corrosion inhibitors asebenza kahle kakhulu ukuvimbela ukugqwala kwensimbi kanye ne-hydrogen embrittlement, nokucindezela ukukhiqizwa kwenkungu ye-asidi.Ikakhulukazi efanelekayo ama-workpieces amancane futhi ayinkimbinkimbi, ayifanele ukumbozwa, ephakeme kunemikhiqizo efanayo emakethe.

Ngokusho kobunzima bensimbi engagqwali kanye nesikali se-oxide, isisombululo sokuqala singasetshenziswa noma sihlanjululwe ngamanzi ngesilinganiso se-1: 1: 1-4 ngaphambi kokusetshenziswa;I-Ferrite, i-Martensite nensimbi engagqwali ye-austenitic enokuqukethwe kwe-nickel ephansi (okufana ne-420.430.200.201.202.300. Ngemva kokuhlanjululwa, insimbi engagqwali ye-austenitic enokuqukethwe okuphezulu kwe-nickel (okufana no-304), 321.316.316L; isixazululo esisitoko, njll.)Ngokuvamile, ngemva kokushisa okujwayelekile noma ukushisa kufika ku-50 ~ 60 ℃, cwilisa imizuzu engu-3-20 noma ngaphezulu (isikhathi esiqondile nezinga lokushisa kuzonqunywa umsebenzisi ngokwesimo sokuhlola) kuze kube yilapho ukungcola okungaphezulu kususwe ngokuphelele, okumhlophe okusasiliva ngokulinganayo. , ukwakha umfaniswano kanye nefilimu ye-passive eminyene.Ngemuva kokwelashwa, yikhiphe, uyigeze ngamanzi ahlanzekile, futhi uyinciphise ngamanzi ane-alkaline noma i-Limewater.

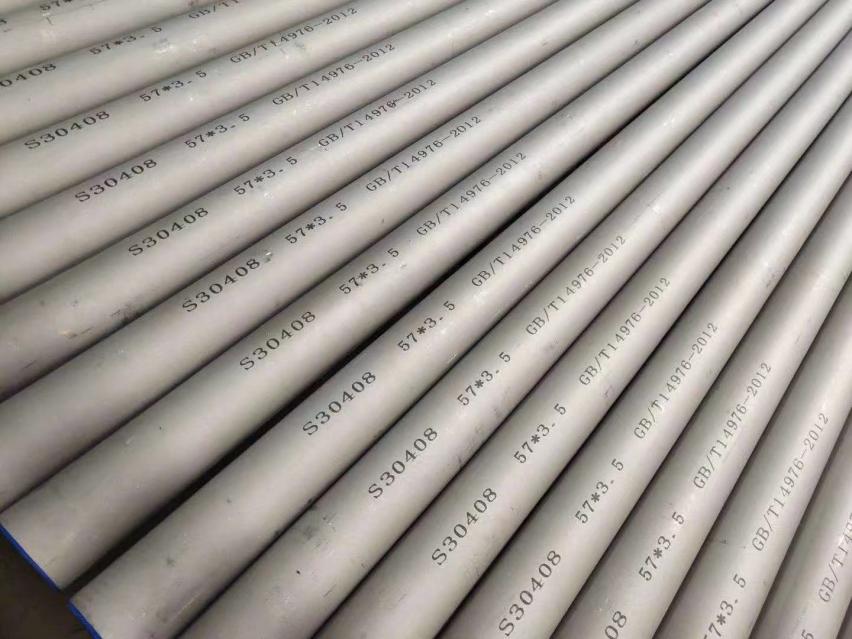

Isidingo sensimbi engagqwali pickling kanye passivation

Insimbi engagqwali inokumelana nokugqwala okuhle, ukumelana ne-oxidation yezinga eliphezulu lokushisa, ukusebenza okuhle kwethempelesha eliphansi, kanye nezakhiwo ezinhle zemishini kanye ne-R.Ngakho-ke, isetshenziswa kabanzi kumakhemikhali, i-petroleum, amandla, ubunjiniyela beNyukliya, i-aerospace, olwandle, imithi, imboni yokukhanya, izindwangu kanye neminye imikhakha.Inhloso yawo enkulu ukuvimbela ukugqwala nokugqwala.Ukumelana nokugqwala kwensimbi engagqwali ikakhulukazi kuncike kwifilimu ye-surface passivation.Uma ifilimu ingaphelele noma inesici, insimbi engagqwali isazogqwala.I-Acid pickling kanye ne-passivation kuvame ukusetshenziswa kubunjiniyela ukuze kuthuthukiswe ukumelana nokugqwala kwensimbi engagqwali.Ngesikhathi sokubunjwa, ukuhlanganisa, ukushisela, ukuhlolwa kwe-weld (njengokubona amaphutha, ukuhlolwa kwengcindezi), kanye nenqubo yokumaka yokwakha yemishini yensimbi engagqwali kanye nezingxenye, amabala kawoyela angaphezulu, ukugqwala, ukungcola okungeyona insimbi, ukungcola kwensimbi okuphansi, upende, i-slag yokushisela, nama-splashes angathinta ikhwalithi ephezulu yensimbi engagqwali nezingxenye, kulimaze ifilimu ye-oxide ebusweni bazo, kunciphise ukugqwala okuphelele nendawo kwensimbi (okubandakanya ukugqwala kwe-pitting), ukugqwala kwegebe), futhi kuholele ekuqhekekeni kokugqwala kwengcindezi. .

Ukuhlanza ubuso bensimbi engagqwali, i-pickling kanye ne-passivation akukwazi nje ukuthuthukisa ukumelana nokugqwala kuze kube sezingeni eliphezulu, kodwa futhi kuvimbele ukungcoliswa komkhiqizo futhi kuzuze imiphumela yobuhle.I-GBl50-1998 “Izitsha Zokucindezela Zensimbi” ibeka ukuthi indawo engaphezulu kweziqukathi ezenziwe ngensimbi engagqwali namapuleti ensimbi ayinhlanganisela kufanele afakwe emanzini anosawoti futhi adlule.Lo mthethonqubo usebenza emikhunjini yokucindezela esetshenziswa embonini ye-petrochemical.Njengoba lezi zisetshenziswa zisetshenziswa ezimeni lapho zihlangana khona ngqo nemithombo yezindaba ebolayo, kuyadingeka ukuphakamisa ukucotshwa kwe-asidi nokudlula ngokombono wokuqinisekisa ukumelana nokugqwala nokumelana nokugqwala.Kweminye imikhakha yezimboni, uma kungekona ukuvimbela ukugqwala, kusekelwe kuphela ezidingweni zokuhlanzeka kanye nobuhle, kuyilapho insimbi engagqwali ayidingi i-pickling ne-passivation.Kodwa izinsimbi zensimbi engagqwali nazo zidinga i-pickling kanye ne-passivation Kwezinye izinto zamakhemikhali ezinezidingo eziqinile zokusetshenziswa, ngaphezu kokuhlanza i-asidi kanye nokunciphisa, i-high purity medium izophinde isetshenziselwe ukuhlanza okuhle kokugcina noma ukuhlanzwa kwemishini, ukuqedela amakhemikhali kanye ne-Electropolishing.

Izimiso ze-Stainless Steel Pickling and Passivation

Ukumelana nokugqwala kwensimbi engagqwali kubangelwa ikakhulukazi ukuthi indawo engaphezulu imbozwe ngefilimu encane kakhulu (cishe 1) nm) ecinene, ehlukanisa indawo ebolayo futhi esebenza njengesithiyo esiyisisekelo sokuvikela insimbi engagqwali.I-stainless steel passivation inezici eziguquguqukayo futhi akufanele ithathwe njengokuqedwa ngokuphelele kokugqwala.Esikhundleni salokho, kufanele kwakhiwe isendlalelo sesithiyo sokusabalalisa, sinciphise kakhulu izinga lokusabela kwe-anode.Ngokuvamile, uma kukhona i-ejenti yokunciphisa (njenge-chloride ion), i-membrane ivame ukulimaza, futhi uma kukhona i-oxidizing agent (efana nomoya), ulwelwesi lungagcinwa noma lulungiswe.

Izinto zokusebenza zensimbi engagqwali ezibekwe emoyeni zizokwakha ifilimu ye-oxide, kodwa ukuvikela kwazo akuphelele.Ngokuvamile, ukuhlanza okuphelele kwenziwa kuqala, kufaka phakathi ukugeza kwe-alkaline ne-asidi, okulandelwa ukudlula nge-oxidant ukuqinisekisa ubuqotho nokuzinza kwefilimu ye-passivation.Enye yezinhloso zokukhetha ukudala izimo ezivumayo zokwelashwa kwe-passivation kanye nokuqinisekisa ukwakheka kwamafilimu e-passivation aphezulu.Ukugeza nge-asidi kubangela ukugqwala phezu kwensimbi engagqwali enogqinsi oluyisilinganiso esingu-10m.Umsebenzi wamakhemikhali wesisombululo se-asidi ubangela izinga lokuchithwa kwendawo enesici ukuthi libe phezulu kunelezinye izingxenye zomhlaba.Ngakho-ke, ukugeza nge-asidi kungenza yonke indawo ilingane futhi isuse izingozi ezithile ezingaba nokugqwala.Kodwa okubaluleke nakakhulu, ngokukhethwa kwe-asidi kanye nokunciphisa, i-iron ne-iron oxides kuncibilika ngaphezu kwe-chromium ne-chromium oxides, isusa ungqimba lwe-chromium empofu, okuholela ekucebile kwe-chromium ebusweni bensimbi engagqwali.Amandla efilimu ecebile ye-chromium passivation angafinyelela+1.0V (SCE), aseduze namandla ezinsimbi eziyigugu futhi athuthukise ukuzinza kokumelana nokugqwala.Ukwelashwa okuhlukile kwe-passivation nakho kungathinta ukwakheka nokwakheka kwefilimu, ngaleyo ndlela kuthinte ukumelana kwayo nokugqwala.Isibonelo, ngokwelashwa kokuguqulwa kwe-electrochemical, ifilimu ye-passivation ingaba nesakhiwo sezendlalelo eziningi futhi yakhe i-CrO3 noma i-Cr2O3 kungqimba yokuvimbela, noma yakhe ifilimu yengilazi ye-oxide ukuze ithuthukise ukumelana nokubola kwensimbi engagqwali.

1.Insimbi engagqwali pickling kanye passivation indlela

Indlela ye-impregnation isetshenziselwa izingxenye ezingafakwa ku-pickling noma amathangi e-passivation, kodwa ayifanele ukusetshenziswa isikhathi eside kwesisombululo se-pickling kumishini emikhulu, ngokusebenza kahle kokukhiqiza okuphezulu kanye nezindleko eziphansi;Imishini yevolumu enkulu igcwele isisombululo se-asidi, futhi ukusetshenziswa koketshezi lokucwiliswa kuphezulu kakhulu.

Ifanele ukusebenza kwangaphakathi kwendawo kanye nokusebenza ngokomzimba kwemishini emikhulu.Izimo zokusebenza ezimbi kanye nokungakwazi ukubuyisela isisombululo se-asidi.

Indlela yokunamathisela isetshenziswa ezindaweni zokufaka noma zokulungisa, ikakhulukazi emisebenzini yezandla emnyangweni we-welding.Izimo zabasebenzi zimbi futhi nezindleko zokukhiqiza ziphezulu.

Indlela yokufutha isetshenziswa endaweni yokufaka, enevolumu ephansi ye-liquid odongeni lwangaphakathi lweziqukathi ezinkulu, izindleko eziphansi, kanye nesivinini esisheshayo, kodwa idinga ukumiswa kwesibhamu sokufutha kanye nesistimu yokujikeleza.

Indlela yokusabalalisa isetshenziselwa izinto ezinkulu, njengezishintshisi zokushisa.Ukwakhiwa kwe-tube kanye nokwelashwa kwegobolondo kulula, futhi isisombululo se-asidi singasetshenziswa kabusha.Kudinga ukuxhunywa kwamapayipi kanye nephampu ohlelweni lokujikeleza.

Izindlela ze-Electrochemical azikwazi ukusetshenziselwa izingxenye kuphela, kodwa futhi nokwelashwa kwangaphandle kwemishini yasendaweni.Ubuchwepheshe buyinkimbinkimbi futhi budinga ugesi we-DC noma i-potentiostat.

2.Pickling kanye passivation izinqubo

Ukukhipha amafutha nokuhlanza ukungcola → Ukugeza ingxenye yokuhlanza amanzi → Ukudlula → Ukugeza ngamanzi ahlanzekile → Ukushisa okomile

3.Pretreatment ngaphambi pickling and passivation

3.1 Ngokwezidingo zemidwebo kanye nemibhalo yokucubungula, yenza i-acid pickling kanye ne-passivation pre-treatment ezitsheni zensimbi engagqwali noma izingxenye ngemuva kokukhiqiza.

3. Weld seam kanye welding slag nhlangothi zombili.Hlanza ama-splash, futhi usebenzise uphethiloli noma into yokuhlanza ukuze ususe amabala kawoyela nokunye ukungcola okungaphezulu kwezingxenye zokucubungula iziqukathi.

3.3 Lapho ukhipha izinto zangaphandle ezinhlangothini zombili zomthungo wokushisela, sebenzisa ibhulashi lensimbi engagqwali, ifosholo lensimbi engagqwali noma isondo lokugaya ukuze uzisuse, futhi uzihlambulule ngamanzi ahlanzekile (ngokuqukethwe kwe-ion ye-chloride engeqile ku-25mg/l).

Uma ibala lamafutha linzima, sebenzisa isisombululo se-alkaline esingu-3-5% ukuze ususe ibala lamafutha bese uhlanza kahle ngamanzi ahlanzekile.

3. Ukuqhuma kwesihlabathi ngomshini kungasusa isikhumba se-oxide sensimbi engagqwali izingxenye ezishisayo, futhi isihlabathi kufanele sibe i-silicon emsulwa noma i-aluminium oxide.

3.6 Ukuthuthukisa izindlela zokuphepha zokukhetha nokudlula, futhi unqume amathuluzi adingekayo kanye nempahla yokuvikela abasebenzi.

4.I-Acid pickling, isisombululo se-passivation kanye nefomula yokunamathisela

4.1 Ifomula yesisombululo sokugeza i-asidi: i-nitric acid (1).42) 20%, hydrofluoric acid 5%, kanti okunye amanzi.Okungenhla yiphesenti levolumu.

4.2 Ifomula yekhilimu yokuhlanza i-Acid: amamililitha angu-20 e-hydrochloric acid (isilinganiso 1.19), amamililitha angu-100 amanzi, amamililitha angu-30 e-nitric acid (isilinganiso 1.42), namagremu angu-150 we-bentonite.

4. Ifomula yesisombululo se-passivation: i-nitric acid (isilinganiso 1).42) 5%, Potassium dichromate 4g, okunye amanzi.Iphesenti elingenhla lokuwa, izinga lokushisa le-passivation yizinga lokushisa legumbi.

4.4 I-passivation paste formula: 30ml nitric acid (concentration 67%), 4g Potassium dichromate, engeza i-bentonite (100-200 mesh) bese ugoqa ukuze unamathisele.

5.I-Acid pickling kanye nokusebenza kwe-passivation

5.1 Iziqukathi kuphela noma izakhi ezike zalashwa ngaphambi kwesikhathi zingathathwa futhi zikwazi ukwelapha.

5. 2 Isixazululo se-Acid pickling sisetshenziselwa ikakhulukazi ukwelashwa okuphelele kwezingxenye ezincane ezingacutshungulwa, futhi zingafuthwa.Izinga lokushisa lesixazululo kufanele lihlolwe njalo ngemizuzu eyi-10 ekushiseni okungama-21-60 ℃ kuze kube yilapho sekukhona ukuqoshwa kwe-asidi emhlophe efanayo.

5.3 I-Pickling Paste I-Pickling ifaneleka kakhulu iziqukathi ezinkulu noma ukucubungula kwendawo.Emazingeni okushisa asekamelweni, hlanza ngokulinganayo ukunamathisela okugcotshwa emishinini (ugqinsi olungaba ngu-2-3mm), uyishiye ihora elilodwa, bese uxubha ngobumnene ngamanzi noma ngebhulashi lensimbi engagqwali kuze kuvele iyunifomu emhlophe ye-acid etching.

5.4 Isixazululo se-passivation sifaneleka kakhulu ukuphathwa kweziqukathi ezincane noma izingxenye ezithile, futhi singacwiliswa noma sifuthwe.Uma izinga lokushisa lesixazululo lingu-48-60 ℃, hlola njalo ngemizuzu engu-20, futhi lapho izinga lokushisa lesisombululo lingu-21-47 ℃, hlola njalo ngehora kuze kube yilapho kwakheka ifilimu yokulinganisa iyunifomu phezulu.

5.5 I-passivation paste ifaneleka kakhulu iziqukathi ezinkulu noma ukucubungula kwendawo.Isetshenziswa ngokulinganayo ebusweni besitsha esifakwe emanzini anosawoti (cishe u-2-3mm) ekamelweni lokushisa futhi ihlolwe ihora elingu-1 kuze kube yilapho kwakhiwa ifilimu ye-passivation efanayo phezulu.

5.6 Iziqukathi zokugcotshwa kwe-asidi kanye ne-passivation noma izingxenye kufanele zigezwe ngamanzi ahlanzekile ngaphezulu., Sebenzisa iphepha lokuhlola i-acidic litmus ukuhlola noma iyiphi ingxenye yendawo egeziwe, ukuze ugeze ingaphezulu ngamanzi anenani le-pH eliphakathi kuka-6.5 no-7.5, bese usula noma uphephethe ngomoya ocindezelweyo.

5.7.Ngemuva kokukhetha kanye nokunciphisa, akuvunyelwe ukunwaya ifilimu ye-passivation lapho uphatha, uphakamisa, futhi ugcina iziqukathi nezingxenye.

Isikhathi sokuthumela: Aug-08-2023