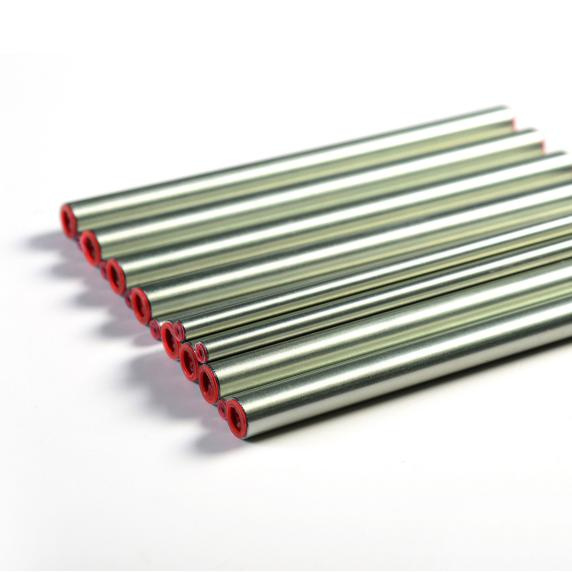

Ekukhiqizweni kwezimboni zanamuhla, izikhundla zemishini ekhethekile ziya ngokuya zisetshenziswa, futhi amapayipi ensimbi angenamthungo awuhlobo olujwayelekile.Kuhle ukusho ukuthi amapayipi ensimbi angenasici ashisayo-dip anokusebenza okuhle, ikhwalithi enhle, impilo ende yesevisi, futhi abonise ukusebenza okuhle kakhulu ekukhiqizeni izimboni zanamuhla, ezikhethwe amabhizinisi amaningi ezimboni.Ngakho, iyiphi indima yalo eyinhloko?Umphumela wokuqala ukuthi ukugqoka kufana, futhi ukunamathela okubonisayo kunamandla kakhulu.Abaphathi abasebenzisa ezinye izinto zokusebenza ukukhiqiza imikhiqizo bangase babe nama-coatings angalingani, abushelelezi, noma angalingani ngaphezulu.Nokho, amapayipi ensimbi angenamthungo adiphu ashisayo ahluke ngokuphelele.Ungqimba lwawo ongaphezulu lwenziwe ngezinto ezishisayo zokucwilisa, ezisetshenziswa ngokulinganayo futhi zikwazi ukunamathela kahle kumapayipi ensimbi angenamthungo, okubonisa ukunamathela okuqinile okukhulu.Umsebenzi wesibili ukuthi ukujwayela kwayo kunesikhathi eside sokuphila kanye nesikhathi eside sokusetshenziswa, okungase kukhulise ukusebenza kwayo.Ngokombono wesimiso senqubo, lapho kusetshenziswa izinto ezishisiwe ezifakwe emanzini ashisayo, isinyathelo sokuqala ukucosha i-asidi echwepheshile epayipini lensimbi, ukususa ngempumelelo izingxenye ezithile ze-iron oxide ezinamathiselwe ebusweni bepayipi lensimbi, bese usebenzisa idiphu elishisayo. izinto zikathayela kuwo, zakha ipayipi lensimbi elingenamthungo elidiphu elishisayo.Ngokusebenzisa lesi simiso, isikhathi sokuphila sepayipi yensimbi ekhiqizwa yinde kakhulu, futhi kunezinkinga ezimbalwa noma ukushiyeka kuyo yonke inqubo yesicelo, engeke ithinte ukusetshenziswa kwayo okusebenzayo.

Umthelela wokusebenza weukunemba amapayipi ensimbi

1. Ikhabhoni;Ukuphakama kwekhabhoni, kuyanda ubulukhuni bensimbi, kodwa ipulasitiki nokumelana kwayo kuba buthakathaka

2. Isibabule ;Kuwukungcola okuyingozi ensimbi.Insimbi enesulfure ephezulu iqhekeka kalula ngesikhathi sokucubungula ingcindezi emazingeni okushisa aphezulu, okuvame ukubizwa ngokuthi i-thermal brittleness.

3. Phosphorus;Inganciphisa kakhulu ipulasitiki nokumelana nensimbi, ikakhulukazi emazingeni okushisa aphansi, okubizwa ngokuthi i-cold brittleness.Ensimbi yekhwalithi ephezulu, isulfure ne-phosphorus kufanele ilawulwe ngokuqinile.Kodwa-ke, ngakolunye uhlangothi, insimbi ephansi ye-carbon iqukethe amazinga aphezulu e-sulphur ne-phosphorus, engenza kube lula ukusika nokuthuthukisa amandla ensimbi.

4. IManganese ;Ingakwazi ukuthuthukisa amandla ensimbi, yenza buthaka futhi iqede imiphumela emibi yesibabule, futhi ithuthukise ukuqina kwensimbi.Insimbi ephezulu ye-alloy (insimbi ephezulu ye-manganese) enokuqukethwe okuphezulu kwe-manganese inokumelana nokugqokwa okuhle kanye neminye imisebenzi yomzimba

5. I-silicon ;Ingakwazi ukuthuthukisa ubulukhuni bensimbi, kodwa ipulasitiki nokumelana kwayo kuncipha.Insimbi esetshenziselwa izinjongo zikagesi iqukethe inani elithile le-silicon, elingathuthukisa umsebenzi ozibuthe othambile

6. I-Tungsten;Ingakwazi ukuthuthukisa ubulukhuni obomvu namandla okushisa ensimbi, kanye nokumelana nokugqoka kwensimbi

7. I-Chromium;Ingathuthukisa ukuqina nokumelana nokugqoka kwensimbi, ithuthukise ukumelana kwayo nokugqwala kanye nokumelana ne-oxidation

Ungasusa kanjani ukugqwala kumapayipi ensimbi anama-galvanized?

1. Okokuqala, hlanza ingaphezulu lensimbi nge-solvent ukuze ususe noma yiziphi izinto eziphilayo ezingaphezulu,

2. Bese usebenzisa okuthile ukususa ukugqwala (ibhulashi locingo), susa amapulani axegayo noma atshekile, ukugqwala, i-welding slag, njll.

3. Sebenzisa indlela yokugeza i-asidi.

Isikhathi sokuthumela: Aug-24-2023