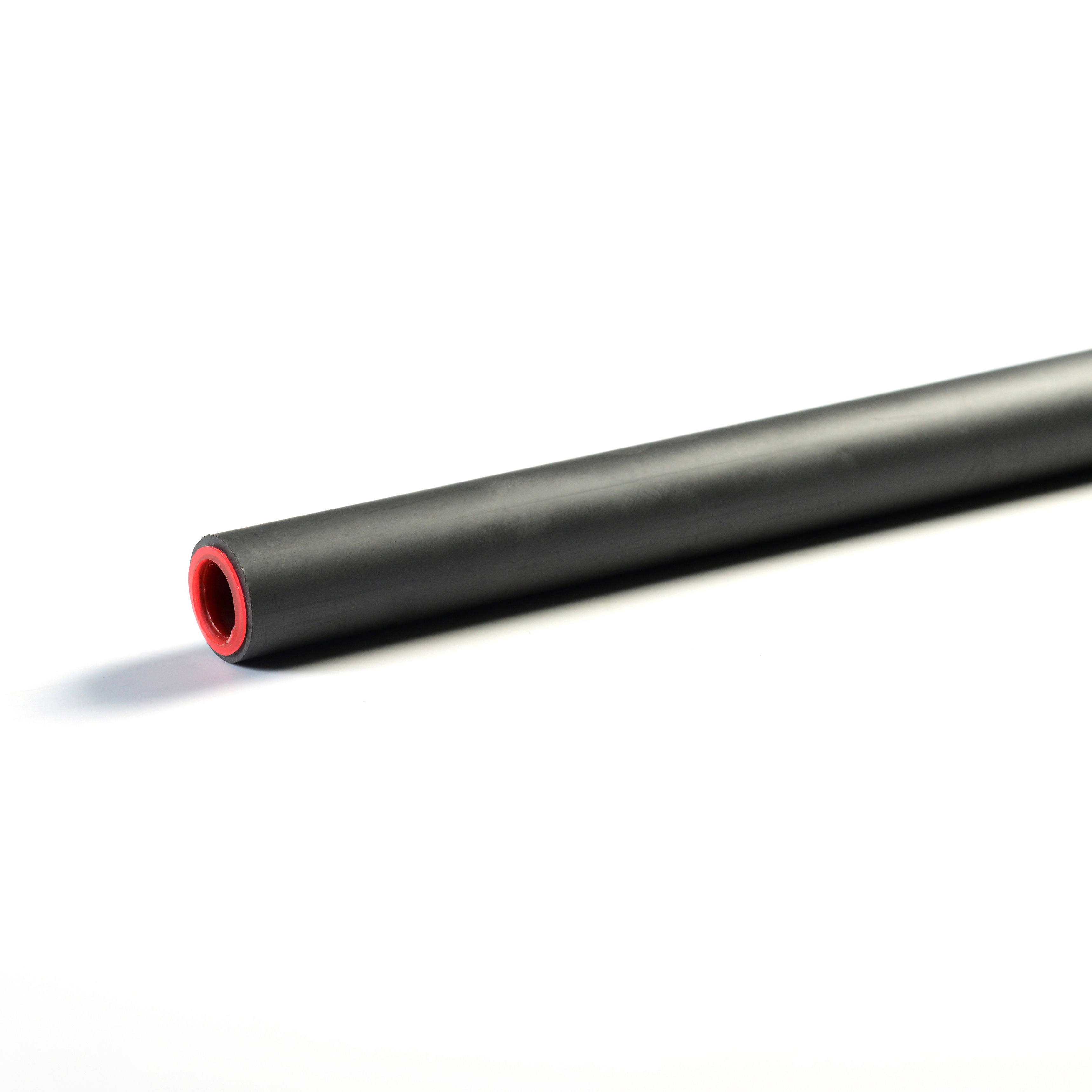

I-Precision phosphatedipayipiiwuhlobo olusha lwepayipi elingagugi, olusebenzisa indlela yokuhlanganisa yokuphotha.Yakhiwa umsebenzi wemishini wokuphotha isidleke esiyinhlanganisela yezinto ezimbili ezihlukene zensimbi eluhlaza ndawonye, kusetshenziswa ngokwesayensi ubukhulu bodonga lwepayipi lesisekelo ukuze lithwale ingcindezi yokusebenza yesistimu yepayipi, futhi lisebenzisa ipayipi lengxubevange elinomugqa elingagqwali ukuthwala izidingo zokugqwala zesistimu yamapayipi.

Uma kuqhathaniswa nensimbi eyingxube yengxube eqinile engagqoki, insimbi engagugi, ipayipi eliyinhlanganisela yensimbi yobumba, kanye nepayipi letshe elibunjiwe, le phosphat enemba.ed ipayipi inezinzuzo ezilandelayo.

1. Ukumelana nokugqoka okuhle.

2. Ukumelana nokucindezela okuphezulu, okulungele amazinga aphezulu okucindezela.

3. I-lining yangaphakathi ihlanganiswe ngokuqinile nepayipi yensimbi yangaphandle, futhi inqubo ekhethekile ikhethwa ukwakha ukuhlanganiswa kwe-fusion phakathi kwezingqimba ezihlanganisiwe, ukuqinisekisa ukuthembeka kokusebenza.

4. Inokumelana okuhle nokushaqeka kwemishini nokushaqeka kokushisa.

5. Uxhumano lwedivayisi olulula.Ama-flanges namajoyinti aguquguqukayo angasetshenziselwa ukuxhumana, futhi angasikwa noma ashiselwe ngokuthanda kwakhe.

Ububanzi bokusetshenziswa:

Isistimu yokudlulisa impushana yamalahle, ipayipi elimanzi elomile elihambisa umlotha, kanye nesistimu yamalahle yamatshe ezimbonini zamandla ashisayo

Amanye amasistimu okudlulisa umoya wezinhlayiya zempushana

IHydraulic slag transportation system kanye nokuthuthwa kwe-slurry enosayizi wezinhlayiyana ezinkulu

Ukuthuthwa kwezinto ezihlukahlukene zezimayini

1. Umphumela we-Phosphating

(1) Umphumela we-phosphating ngaphambi kokugqoka

① Thuthukisa ukunamathela phakathi kwesendlalelo sokumboza (okufana nokupenda ngopende) kanye nendawo yokusebenza.

② Thuthukisa ukumelana nokugqwala kwento engaphezulu yesiqeshana sokusebenza ngemuva kokumbozwa.

③ Thuthukisa umhlobiso.

(2) Umphumela we-non-coating phosphating

① Thuthukisa ukumelana nokuguga kwesiqeshana sokusebenza.

② Qinisekisa ukushelela kwengcezu yokusebenza ngesikhathi somshini.

③ Thuthukisa ukumelana nokugqwala kwendawo yokusebenza.

2. Ukusetshenziswa kwe-phosphating

I-Steel phosphating isetshenziselwa ikakhulukazi ukuvikela ukugqwala futhi njengefilimu eyisisekelo yopende.

(1) Ifilimu ye-Phosphating yokuvikela ukugqwala

① Ifilimu ye-phosphating evikelayo isetshenziselwa ukwelashwa kokuvikela ukugqwala kwezingxenye zensimbi.Uhlobo lwefilimu ye-phosphating ingaba i-zinc noma i-manganese.Ubuningi beyunithi ngayinye yendawo yolwelwesi yi-10-40 g/m2.Faka amafutha e-anti rust, amafutha, i-wax, njll. ngemva kwe-phosphating.

② Ifilimu ye-Phosphating ye-substrate kapende

Khulisa ukunamathela nokuvikela phakathi kwefilimu kapende nezinto zokusebenza zensimbi.Uhlobo lwefilimu ye-phosphating ingaba i-zinc esekelwe noma i-zinc calcium esekelwe.Ubuningi bendawo yeyunithi yefilimu ye-phosphating yi-0.2-1.0 g/m2 (esetshenziselwa ungqimba olungezansi lopende ezingxenyeni ezinkulu zensimbi ye-deformation);1-5 g/m2 (esetshenziselwa ungqimba olungezansi lopende ezingxenyeni zensimbi ezijwayelekile);5-10 g/m2 (okwesendlalelo sesisekelo sikapende sezingxenye zensimbi ezingenzi ukuguqulwa).

(2) Ukumbozwa kwe-phosphate ukuze kube lula ukusebenza okubandayo

Isisindo sefilimu endaweni ngayinye yocingo lwensimbi nomdwebo wepayipi lensimbi elishiselwe ngu-1-10 g/m2;Isisindo sefilimu endaweni ngayinye ye-precision phosphating tube drawing yi-4-10 g/m2;Isisindo sefilimu endaweni ngayinye ye-extrusion ebandayo eyenza izingxenye zensimbi sikhulu kuno-10 g/m2.

(3) I-Phosphate coating yokunciphisa ukungqubuzana

Ifilimu ye-Phosphating inganciphisa ukungqubuzana.Ngokuvamile, i-phosphating esekelwe ku-manganese isetshenziswa, futhi i-zinc based phosphating ingasetshenziswa.Kuma-workpiece anezikhala ezincane eziguquguqukayo ezifanele, ubukhulu befilimu ye-phosphating ngu-1-3 g/m2;Okwezinto zokusebenza ezinezikhala ezinkulu eziguqukayo (amagiya ebhokisi legiya), isisindo sefilimu ye-phosphating ngu-5-20 g/m2.

(4) I-Phosphate coating yokufakelwa kukagesi

Ngokuvamile, i-zinc based phosphating isetshenziswa.Isetshenziselwa ukwelashwa kwe-silicon wafer phosphating kumamotho kanye nama-transformer.

Isikhathi sokuthumela: Aug-24-2023