Ibha Yensimbi Eyindilinga ye-SAE8620H /GB 20CrNiMo Steel Bar

Izici

Insimbi ye-8620 alloy yakhiwe (ngokuhlelwa kokwehla kwephesenti) insimbi, ikhabhoni, i-silicon, i-molybdenum, i-manganese, i-nickel, i-chromium, isulfure ne-phosphorus.Lezi zakhi zesithako kufanele zibe phakathi kwamaphesenti athile esisindo ukuze udale ingxubevange engu-8620.Kunconywa ukuthi insimbi iqiniswe yi-carburization elandelwa namafutha, ngokuphambene namanzi, cisha.Inesilinganiso esimaphakathi sokuminyana kwama-alloys ensimbi angu-.28 lb. per inch square, nakuba amandla ayo aqinile - inani lesisindo engakwazi ukulibamba ngaphambi kokuphuka - liphansi, ku-536.4 Mpa.Isilinganiso samandla ensimbi ama-alloys angama-758 kuya ku-1882 Mpa.

Lapho ingxubevange ye-8620 ishiswe ngendlela efanele - ishisiswe kumazinga okushisa amisiwe bese ivezwa kumenzeli oqukethe ikhabhoni, inqubo enezela ungqimba olwengeziwe lwekhabhoni ngaphandle kwensimbi, ngaleyo ndlela iyenze ibe namandla - isetshenziselwa ukwenza umshini onjalo. izingxenye njengamagiya, ama-crankshafts, namaringi egiya.I-Carburized 8620 alloy inamandla futhi ihlala isikhathi eside, yingakho ikhethwa kulezi zingxenye.

IZINGA: ASTM A29/A29M-2012

Ukwakheka kwamakhemikhali

| Ikhabhoni C | 0.17~0.23 |

| Silicon Si | 0.15~0.35 |

| Manganese Mn | 0.65~0.95 |

| Isibabule S | ≤ 0.025 |

| I-Phosphorus P | ≤ 0.025 |

| I-Chromium Cr | 0.35~0,65 |

| I-Nickel | 0.35-0.65 |

| I-Copper Cu | ≤ 0.025 |

| Molybdenum Mo | 0.15-0.25 |

Izakhiwo zemishini

| amandla e-tensile σ b (MPa) | ≥980(100) |

| yield strength σ s (MPa) | ≥785(80) |

| ubude δ 5 (%) | ≥9 |

| Ukwehliswa kwendawo ψ (%) | ≥40 |

| Impact energy Akv (J) | ≥ 47 |

| Inani lokuqina lomthelela α kv (J/cm2) | ≥59(6) |

| Ukuqina | ≤ 197HB |

| Inqubo | I-EAF+LF+VOD+Forged+Heat Treatment(kuyakhetheka) |

| SIZE UBANGO | |

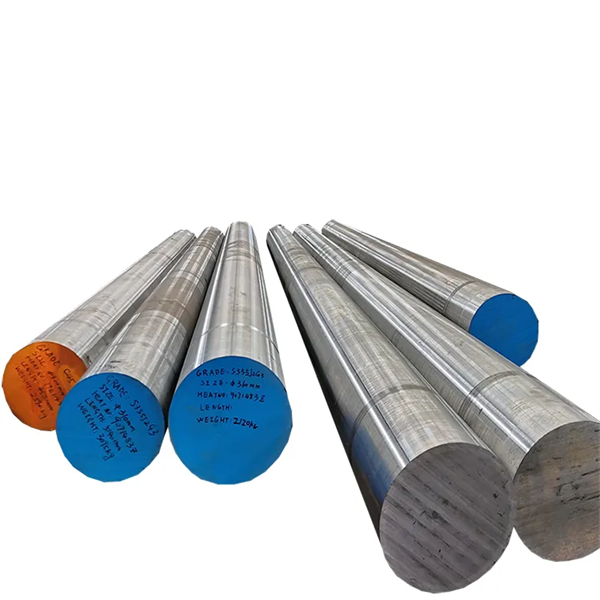

| Umjikelezo | 10mm ukuze 360mm |

| UBUSE BUYAQEDA | Mnyama, Ehlutshiwe (K12), Ebandayo Edwetshiwe, Ephendukile futhi Epholishiwe (H10, H11), Precision Ground (H9, H8) |

Ukwelashwa Kokushisa

| Ukusebenza okushisayo | 850-1150oC |

| Ukuqina kwecala | I-Hardenngo ephindwe kabili |

| I-Carburising | 900-950oC |

| Ukushisa okuthambile | 650-700oC |

| Ukuqina kobuso | 800-930oC |

| Ukuthukuthela | 150-210oC |

| Ukuhlolwa kwe-Ultrasonic | Ngokusho kwe-SEP 1921-84 |

Isitifiketi Sekhwalithi: sikhishwe ngesiNgisi, ngaphezu kwalokho imigomo evamile, inqubo yokukhiqiza, impahla engumshini (amandla okukhiqiza, amandla aqinile, ubude nokuqina), isilinganiso esihlanganisiwe, umphumela wokuhlolwa kwe-UT, usayizi wokusanhlamvu, izindlela zokwelapha ukushisa kanye nesampula kuboniswe kusitifiketi sekhwalithi.

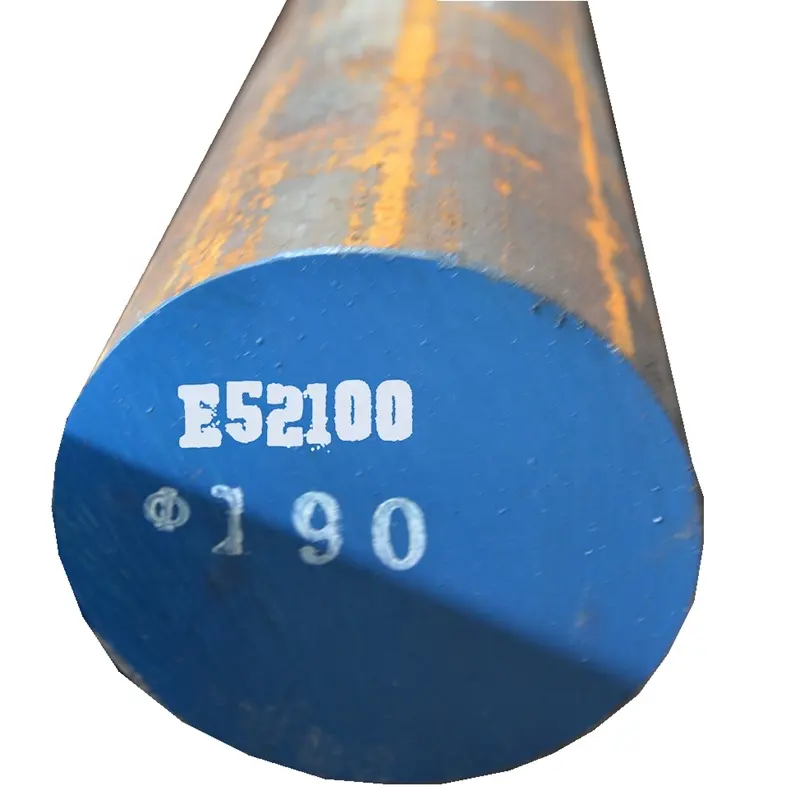

Ukumaka: Inombolo Yokushisa izogxivizwa ngendlela ebandayo futhi ibanga lensimbi, ububanzi (mm), ubude (mm), kanye ne-LOGO yomkhiqizi nesisindo (kg) kupendiwe.

Amazinga Alinganayo

| ASTM&AISI&SAE | I-JIS | EN DIN | EN BS | EN NF | ISO | GB |

| 86208620H | I-SNCM220 | 1.6523 | 1.6523 | 1.6523 | ------ | 20CrNiMo |

Isicelo sebha yensimbi ye-SAE8620H

Okuvame ukusetshenziselwa ukukhiqiza izingxenye ezibalulekile ezinamandla amakhulu kanye nepulasitiki enhle, kanye nokukhiqiza izingxenye ezibalulekile ezinezidingo ezikhethekile zokusebenza ngemuva kokwelashwa kwe-nitriding:

Ama-arbors, ama-bushings, abalandeli be-Cam, izikhonkwane zokugqoka, ama-bearings, ama-sprockets, amagiya nama-shafts, izinja ze-Clutch, ama-Compressor bolts, ama-extractors, ama-fan shafts, ama-Heavy Duty Gears, ama-Pump Shafts, ama-Sprocket, ama-Tappets, ama-Wear pin, ama-Wire Guide njll. Noma ingasetshenziselwa izinhlelo zokusebenza ezishubile kakhulu ezingangcwatshwanga kodwa ngokuqiniswa nokufutheka.Isetshenziswa kakhulu yiyo yonke imikhakha yezimboni yezingxenye namashafti adinga ukumelana nokugqoka okuphezulu, amandla aphezulu aphezulu kanye nezakhiwo ezinomthelela.

Iphakheji

1.Ngezinqwaba, isisindo senqwaba ngayinye singaphansi kwamathani ama-3, kokuncane kwangaphandleIbha eyindilinga enobubanzi, inyanda ngayinye enemicu yensimbi engu-4 - 8.

Isiqukathi esingamamitha angu-2.20 siqukethe ubukhulu, ubude obungaphansi kuka-6000mm

Isiqukathi esingamamitha angu-3.40 siqukethe ubukhulu, ubude obungaphansi kuka-12000mm

4.Ngomkhumbi omningi, Inkokhelo Yempahla iphansi ngempahla eyinqwaba, futhi inkuluosayizi abasindayo abakwazi ukulayishwa ezitsheni zokuhambisa ngempahla enkulu

Ukuqinisekisa ikhwalithi

1. Qinisa Ngokuvumelana Nezimfuneko

2. Isampula: Isampula iyatholakala.

3. Izivivinyo: Ukuhlolwa kwesifutho sikasawoti / Ukuhlolwa kwe-Tensile / Ukuhlolwa kwe-Eddy yamanje / Ukwakheka kwamakhemikhali ngokwesicelo samakhasimende

4. Isitifiketi: IATF16949, ISO9001, SGS njll.

5. EN 10204 3.1 Isitifiketi