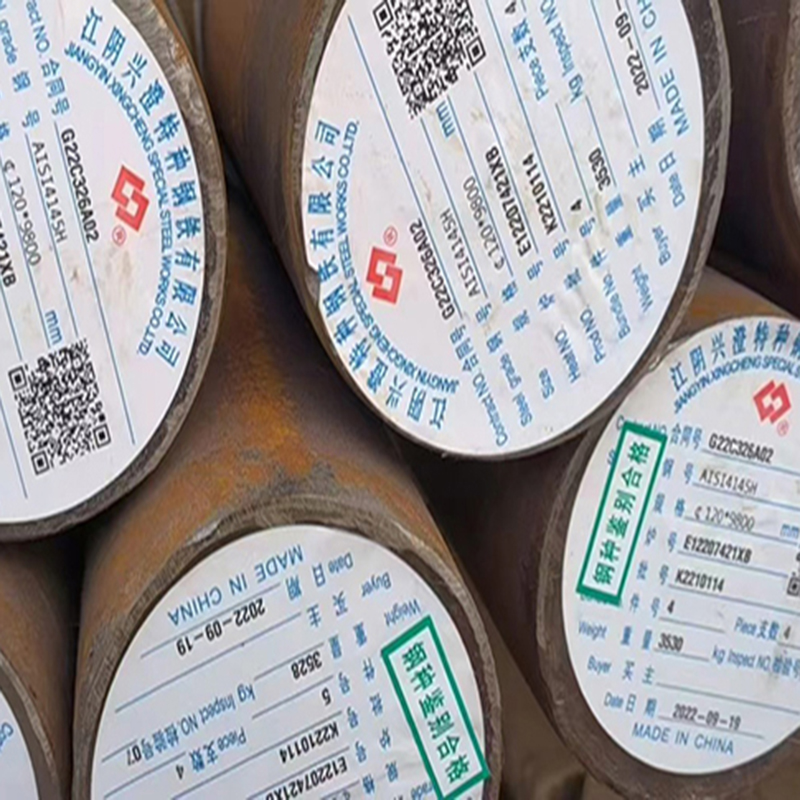

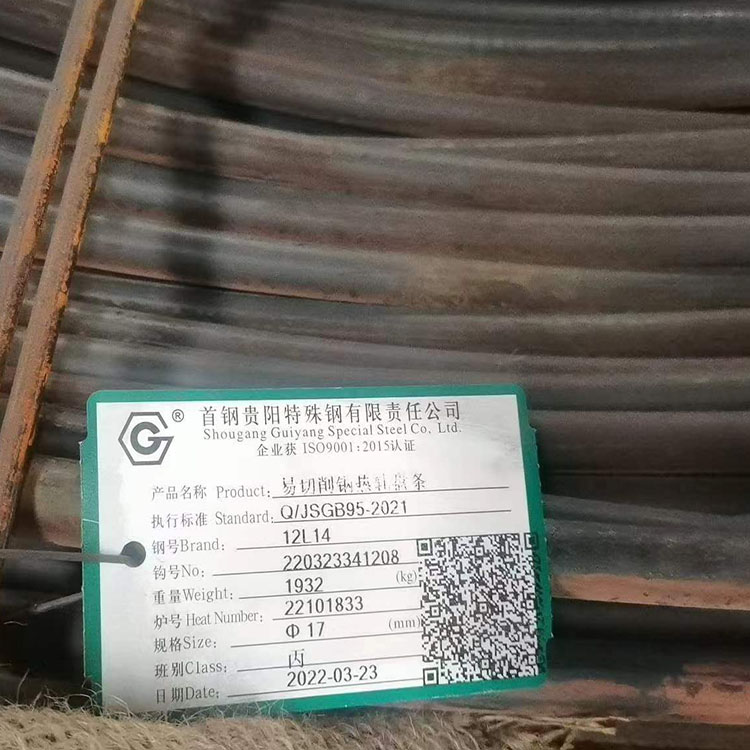

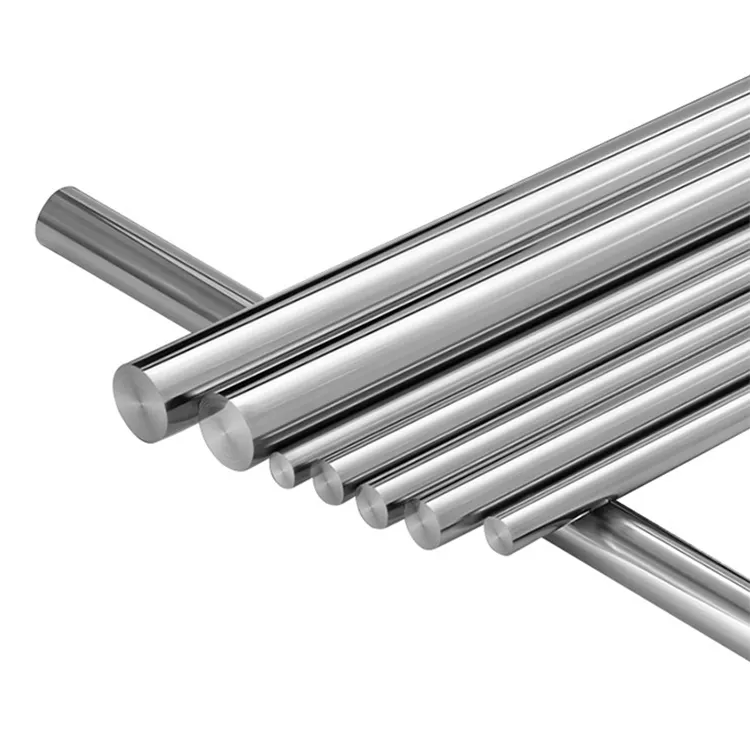

SAE4130 Steel Round Bar AISI 4130 Ingxubevange Steel Bar

Siphishekela imfundiso yokuphatha ethi "Ikhwalithi iyingqayizivele, Usizo luphakeme, Idumela kuqala", futhi sizodala futhi sabelane ngempumelelo nawo wonke amaklayenti e-SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Siphinde sizingela ngokuqhubekayo ukuze sisungule ubuhlobo abahlinzeki abasha ukuze banikeze okunye okuthuthukayo nokuhlakaniphile kubathengi bethu abayigugu.

Siphishekela imfundiso yezokuphatha ethi "Ikhwalithi iyingqayizivele, Usizo luphakeme, Idumela lokuqala", futhi sizodala futhi sabelane ngempumelelo nawo wonke amakhasimende4130 Ibha Yensimbi, Sithemba ukuthi singasungula ukubambisana kwesikhathi eside nawo wonke amakhasimende.Futhi sithemba ukuthi singathuthukisa ukuncintisana futhi sifinyelele isimo sokuwina kanye namakhasimende.Samukela ngobuqotho amakhasimende avela emhlabeni wonke ukuthi axhumane nathi nganoma yini oyidingayo!

Izici

4130 4135 4140 4145H imigoqo yensimbi iyinsimbi ephansi ye-carbon alloy.Zingeze-Chrome-Molly alloy equkethe i-chromium ne-molybdenum njengama-ejenti aqinisayo.

Ibha yensimbi eyindilinga engu-4130 inekhono elihle lomsebenzi, ukuguquguquka okuncane kokucubungula, nokumelana nokukhathala okuhle kakhulu.Iyingxenye yensimbi enekhono eliqinile eliphakathi nendawo ukuya phezulu.Ngemuva kokwelashwa okushisa, i-4140 inamandla amahle kanye nezakhiwo eziphelele zemishini, ikhono elihle lenqubo, kanye nesivuno esikhulu.Izinga lokushisa lesevisi lingu-427 degrees Celsius.

I-4140 inamandla aphezulu, ikhono eliqinile, ukuqina, kanye nokuguqulwa ngesikhathi sokucisha.Inamandla aphezulu okukhasa kanye namandla okubekezela emazingeni okushisa aphezulu.Isetshenziselwa ukukhiqiza ama-forging adinga amandla aphezulu kanye nezingxenye ezinkulu ezicishiwe neziqinile kunensimbi engu-4135, njengamagiya amakhulu okudonsa kwesitimela, amagiya okudlulisa amandla, ama-asi angemuva, izinduku zokuxhuma neziqeshana zasentwasahlobo ezilayishwe kakhulu.

Ukucaciswa

| Igama Lomkhiqizo | AISI ASTM 4130 4135 4140 Ingxubevange Steel Bar | |

| Okubalulekile | I-ASTM | 4130,4135 4140,4145H |

| I-DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Okujwayelekile | I-GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ukuze 600mm | |

| Ubuso | Okupendiwe okumnyama, Okungenalutho, Okupholishiwe, I-Chrome Plated | |

| Imininingwane | Ibha eyindilinga | 8mm ~ 800mm |

| Ibha ye-engeli | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Ibha yesikwele | 4mm*4mm~100mm*100mm | |

| Ibha eyisicaba | 2*10mm~100*500mm | |

| I-Hexagonal | 4mm ~ 800mm | |

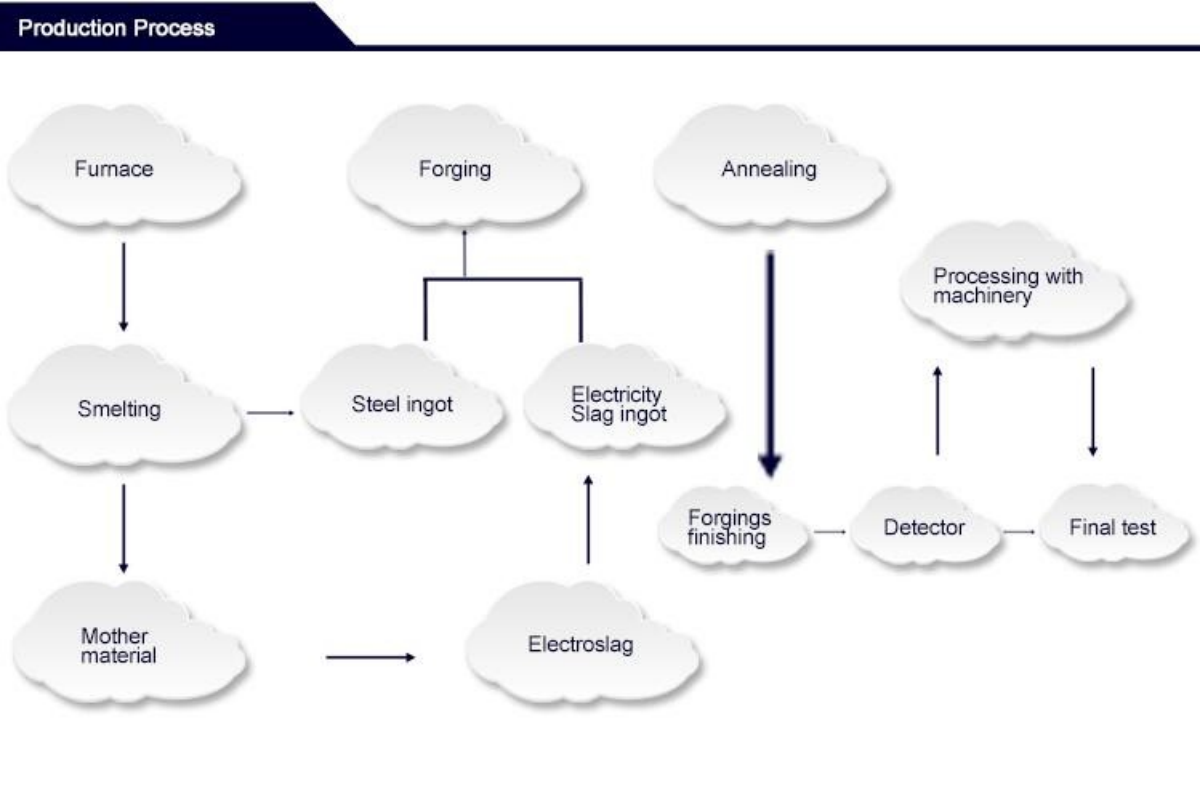

| Inqubo | Isithando somlilo sikagesi sincibilikile, sakhiwe futhi safakwa, ibha eyindilinga ephendukile. | |

| Ukuqina: | I-HBS 217Max (Ihlukile ekwelashweni kokushisa) | |

| Ukuhlolwa kwe-UT | SEP 1921/84/2 C/c ikilasi. | |

| Ukubekezelelana | I-Dia -0/+ 0~5mm, Ukuqina -0/+ 0~5mm, Ububanzi: -0/+ 0~10mm. | |

| Ubude | 2m, 4m, 5.8m, 6m, 11.8m, 12m noma njengoba kudingeka. | |

| Iphakheji | Ukupakisha Okufanele Ulwandle. | |

| Izinga elilinganayo elihlukile | |||

| AISI | GB | I-DIN | I-JIS |

| 4130 | 30CrMo | 1.7218 | I-SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | I-SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | I-SCM432 |

| 4145H | - | - | - |

Ukwakheka Kwamakhemikhali

| Ukwakhiwa Kwekhemikhali (%) | |||||||

| Ibanga | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Izakhiwo Zemishini

| Izici: |

| 1.Insimbi ye-alloy ephansi equkethe i-molybdenum ne-chromium njengama-ejenti aqinisayo; |

| 2.Kuhle kakhulu kumbono we-fusion weldability; |

| 3.I-alloy ingenziwa lukhuni ngokuphathwa ukushisa. |

Ukubekezelelana

| Isimo Sokulethwa |

| 1.Hot rolled |

| 2.Ifakiwe |

| 3.Okujwayelekile |

| 4. Qeda futhi Uthukuthele |

Izimo zokwelashwa kokushisa

1.Annealing: 880℃ Ukupholisa isithando somlilo

2.Ukwejwayelekile: 880~870℃ Ukupholisa komoya

3.Ukuqina: 820~870℃ Ukupholisa amanzi

4.Ukushisa: 550 ~ 650℃ Ukupholisa okusheshayo

Izakhiwo Zemishini zingatholwa ngokwelashwa okuhlukile kokushisa.

Iphakheji

1.Ngezinqwaba, isisindo senqwaba ngayinye singaphansi kwamathani ama-3, kokuncane kwangaphandle

Ibha eyindilinga enobubanzi, inyanda ngayinye enemicu yensimbi engu-4 – 8.

Isiqukathi esingamamitha angu-2.20 siqukethe ubukhulu, ubude obungaphansi kuka-6000mm

Isiqukathi esingamamitha angu-3.40 siqukethe ubukhulu, ubude obungaphansi kuka-12000mm

4.Ngomkhumbi omningi, Inkokhelo Yempahla iphansi ngempahla eyinqwaba, futhi inkulu

osayizi abasindayo abakwazi ukulayishwa ezitsheni zokuhambisa ngempahla enkulu

Ukuqinisekisa ikhwalithi

1.Iqinile ngokwezimfuneko

2. Isampula: Isampula iyatholakala.

3. Izivivinyo: Ukuhlolwa kwesifutho sikasawoti / Ukuhlolwa kwe-Tensile / Ukuhlolwa kwe-Eddy yamanje / Ukwakheka kwamakhemikhali ngokwesicelo samakhasimende

4.Isitifiketi: IATF16949, ISO9001, SGS njll.

5. EN 10204 3.1 Isitifiketi

I-SAE4130 insimbi eyindilinga iyinsimbi yentengo ye-alloy.I-ASTMA29/A29M-04 ejwayelekile.Umkhiqizo wasekhaya ohambelanayo: 30CrMo Umkhiqizo waseJapan ohambisanayo: SCM430 (SCM2) Umkhiqizo waseJalimane ohambelana: 34CrMo4 (1.7220)

Insimbi yesakhiwo engu-4130 inamandla aphezulu kanye nokuqina, ukuqina okuphezulu, kanye nobubanzi obuqinile bokuqina obungu-15-70mm emafutheni;Amandla ashisayo ensimbi nawo mahle, anamandla anele okushisa angaphansi kuka-500 ℃, kodwa amandla ayo ehla kakhulu ku-550 ℃;Lapho i-alloy element isezingeni eliphansi, ukushisela kuhle impela, kepha uma sekusondele umkhawulo ongaphezulu, ukushisela kuphakathi, futhi ukushisa ngaphambi kokufika ku-175 ℃ kuyadingeka ngaphambi kokushisela;Insimbi ine-machinability enhle kanye ne-plasticity emaphakathi ngesikhathi sokuguqulwa okubandayo;Ngesikhathi sokwelashwa kokushisa, kukhona ukufutheka okufanayo kwentukuthelo ebangeni lika-300-350 ℃;Kukhona ukuthambekela kokwenza amabala amhlophe.

I-SAE4130 isetshenziswa kakhulu embonini yokukhiqiza imishini ephakathi nendawo ukwenza izingxenye ezicishiwe nezithambile ezinezingxenye ezinkulu eziphambanayo ezisebenza ngaphansi kwezimo ezicindezelayo, njengama-shafts, ama-spindles, namasondo okulawula umthwalo omkhulu, amabhawodi, amabhawodi amakhanda amabili, amagiya, njll;Isetshenziswa embonini yamakhemikhali ukwenza izingxenye ezishiselwe, izakhiwo ezishiselwe ezakhiwe ngamapuleti namapayipi, kanye namapayipi anomfutho ophezulu onezinga lokushisa elingeqile ku-250 ℃ esebenza endaweni equkethe i-nitrogen ne-hydrogen;Embonini yokukhiqiza ama-turbines nama-boilers, isetshenziselwa ukukhiqiza izinsimbi ezisebenza ngaphansi kuka-450 ℃, ama-flanges namakhava e-flange ngaphansi kwengcindezi ephezulu engaphansi kuka-500 ℃.