SAE 4140 4130 Carbon Steel Round Bars 4140 Steel bar

siyakwazi ukuhlinzeka ngezinto zekhwalithi enhle, isilinganiso esinolaka kanye nosizo lomthengi olungcono kakhulu.Indawo esiya kuyo ithi “Uza lapha ngobunzima futhi sikunikeza ukumamatheka ongahamba nakho” ku-SAE 4140 4130 Carbon Steel Round Bars 4140 Steel Bar, Okwamanje, sifuna ukubambisana okukhulu nakakhulu namathemba aphesheya anqunywa izinzuzo ezifanayo.Sicela uzizwe ukhululekile ukuxhumana nathi ukuze uthole amanye amaqiniso.

siyakwazi ukuhlinzeka ngezinto zekhwalithi enhle, isilinganiso esinolaka kanye nosizo lomthengi olungcono kakhulu.Indawo yethu ithi “Uza lapha ngobunzima futhi sikunikeza ukumamatheka ozohamba nakho”Ibha eyindilinga yensimbi engama-4140, Ukulawulwa kwekhwalithi okuqinile kwenziwa kusixhumanisi ngasinye sayo yonke inqubo yokukhiqiza.Sithemba ngobuqotho ukusungula ukubambisana okunobungane nokuzuzisayo nawe.Ngokusekelwe kuzisombululo zekhwalithi ephezulu kanye nensizakalo efanelekile yokuthengisa kwangaphambili / ngemuva kokuthengisa ingumbono wethu, amanye amaklayenti abambisane nathi iminyaka engaphezu kwemi-5.

Izici

4130 4135 4140 4145H imigoqo yensimbi iyinsimbi ephansi ye-carbon alloy.Zingeze-Chrome-Molly alloy equkethe i-chromium ne-molybdenum njengama-ejenti aqinisayo.

Ibha yensimbi eyindilinga engu-4130 inekhono elihle lomsebenzi, ukuguquguquka okuncane kokucubungula, nokumelana nokukhathala okuhle kakhulu.Iyingxenye yensimbi enekhono eliqinile eliphakathi nendawo ukuya phezulu.Ngemuva kokwelashwa okushisa, i-4140 inamandla amahle kanye nezakhiwo eziphelele zemishini, ikhono elihle lenqubo, kanye nesivuno esikhulu.Izinga lokushisa lesevisi lingu-427 degrees Celsius.

I-4140 inamandla aphezulu, ikhono eliqinile, ukuqina, kanye nokuguqulwa ngesikhathi sokucisha.Inamandla aphezulu okukhasa kanye namandla okubekezela emazingeni okushisa aphezulu.Isetshenziselwa ukukhiqiza ama-forging adinga amandla aphezulu kanye nezingxenye ezinkulu ezicishiwe neziqinile kunensimbi engu-4135, njengamagiya amakhulu okudonsa kwesitimela, amagiya okudlulisa amandla, ama-asi angemuva, izinduku zokuxhuma neziqeshana zasentwasahlobo ezilayishwe kakhulu.

Ukucaciswa

| Igama Lomkhiqizo | AISI ASTM 4130 4135 4140 Ingxubevange Steel Bar | |

| Okubalulekile | I-ASTM | 4130,4135 4140,4145H |

| I-DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Okujwayelekile | I-GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ukuze 600mm | |

| Ubuso | Okupendiwe okumnyama, Okungenalutho, Okupholishiwe, I-Chrome Plated | |

| Imininingwane | Ibha eyindilinga | 8mm ~ 800mm |

| Ibha ye-engeli | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Ibha yesikwele | 4mm*4mm~100mm*100mm | |

| Ibha eyisicaba | 2*10mm~100*500mm | |

| I-Hexagonal | 4mm ~ 800mm | |

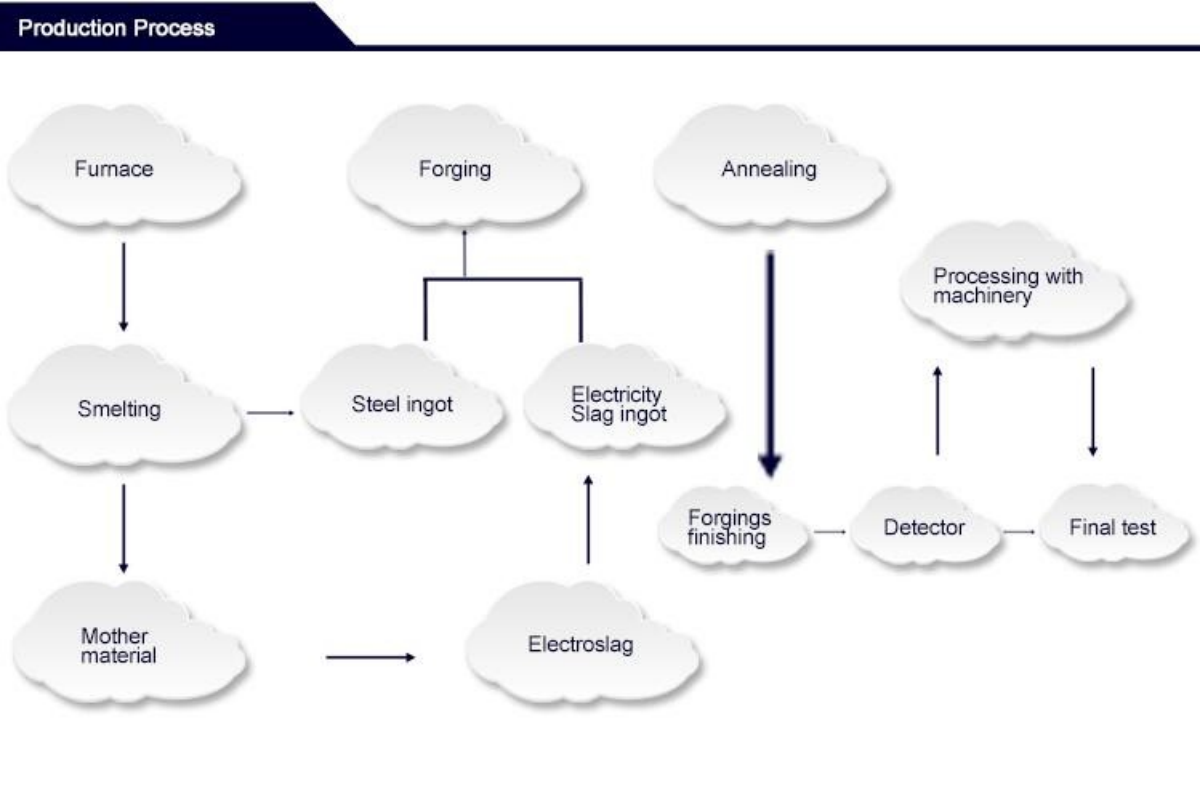

| Inqubo | Isithando somlilo sikagesi sincibilikile, sakhiwe futhi safakwa, ibha eyindilinga ephendukile. | |

| Ukuqina: | I-HBS 217Max (Ihlukile ekwelashweni kokushisa) | |

| Ukuhlolwa kwe-UT | SEP 1921/84/2 C/c ikilasi. | |

| Ukubekezelelana | I-Dia -0/+ 0~5mm, Ukuqina -0/+ 0~5mm, Ububanzi: -0/+ 0~10mm. | |

| Ubude | 2m, 4m, 5.8m, 6m, 11.8m, 12m noma njengoba kudingeka. | |

| Iphakheji | Ukupakisha Okufanele Ulwandle. | |

| Izinga elilinganayo elihlukile | |||

| AISI | GB | I-DIN | I-JIS |

| 4130 | 30CrMo | 1.7218 | I-SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | I-SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | I-SCM432 |

| 4145H | - | - | - |

Ukwakheka Kwamakhemikhali

| Ukwakhiwa Kwekhemikhali (%) | |||||||

| Ibanga | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Izakhiwo Zemishini

| Izici: |

| 1.Insimbi ye-alloy ephansi equkethe i-molybdenum ne-chromium njengama-ejenti aqinisayo; |

| 2.Kuhle kakhulu kumbono we-fusion weldability; |

| 3.I-alloy ingenziwa lukhuni ngokuphathwa ukushisa. |

Ukubekezelelana

| Isimo Sokulethwa |

| 1.Hot rolled |

| 2.Ifakiwe |

| 3.Okujwayelekile |

| 4. Qeda futhi Uthukuthele |

Izimo zokwelashwa kokushisa

1.Annealing: 880℃ Ukupholisa isithando somlilo

2.Ukwejwayelekile: 880~870℃ Ukupholisa komoya

3.Ukuqina: 820~870℃ Ukupholisa amanzi

4.Ukushisa: 550 ~ 650℃ Ukupholisa okusheshayo

Izakhiwo Zemishini zingatholwa ngokwelashwa okuhlukile kokushisa.

Iphakheji

1.Ngezinqwaba, isisindo senqwaba ngayinye singaphansi kwamathani ama-3, kokuncane kwangaphandle

Ibha eyindilinga enobubanzi, inyanda ngayinye enemicu yensimbi engu-4 – 8.

Isiqukathi esingamamitha angu-2.20 siqukethe ubukhulu, ubude obungaphansi kuka-6000mm

Isiqukathi esingamamitha angu-3.40 siqukethe ubukhulu, ubude obungaphansi kuka-12000mm

4.Ngomkhumbi omningi, Inkokhelo Yempahla iphansi ngempahla eyinqwaba, futhi inkulu

osayizi abasindayo abakwazi ukulayishwa ezitsheni zokuhambisa ngempahla enkulu

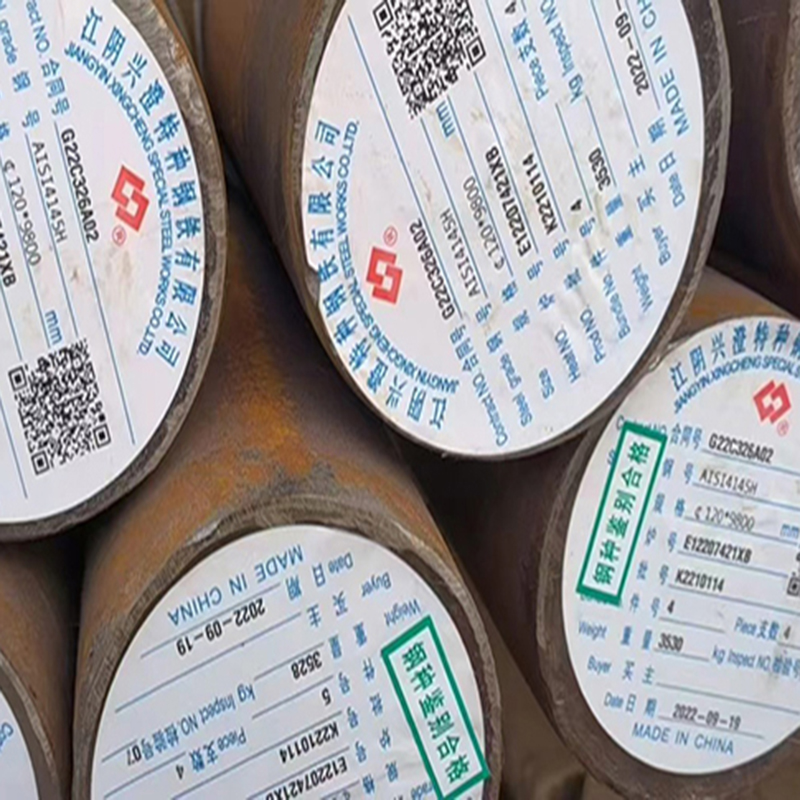

Ukuqinisekisa ikhwalithi

1.Iqinile ngokwezimfuneko

2. Isampula: Isampula iyatholakala.

3. Izivivinyo: Ukuhlolwa kwesifutho sikasawoti / Ukuhlolwa kwe-Tensile / Ukuhlolwa kwe-Eddy yamanje / Ukwakheka kwamakhemikhali ngokwesicelo samakhasimende

4.Isitifiketi: IATF16949, ISO9001, SGS njll.

5. EN 10204 3.1 Isitifiketi

I-SAE 4140 alloy structural steel iyinsimbi evamile enamandla aphezulu enezakhiwo ezinhle zokusebenza nokumelana nokugqokwa, kanye nokucwebezela okuhle ngemva kokugaya.

I-SAE4140 ingxubevange yensimbi yesakhiwo inamandla aphezulu, ukuqina okuphezulu, ukusebenza kahle kakhulu kokwelashwa kokushisa, nokumelana nokugqokwa, okuyenza ibe yinsimbi enhle kakhulu.Le nsimbi inamandla amahle kakhulu nobulukhuni emazingeni okushisa aphezulu, kuyilapho igcina ukuqina okuhle nokumelana nokugqwala.

I-SAE4140 ingxubevange yensimbi yesakhiwo isetshenziswa kabanzi emikhakheni efana nokukhiqizwa kwemishini, ukukhiqizwa kwezimoto, ukwakhiwa kwemikhumbi, i-metallurgy, kanye nemboni ye-petrochemical.Isibonelo, ingasetshenziswa ukwenza izingxenye zemishini ezinamandla aphezulu, njengama-transmission shafts, amagiya, ama-bearings, njll. Ngaphezu kwalokho, ingase futhi isetshenziselwe ukwenza imishini ye-petrochemical efana nezingcezu zokubhoboza i-petroleum kanye nezinkundla zokumba.Ngaphezu kwalokho, i-SAE4140 alloy structural steel ingasetshenziswa futhi ukwenza izingxenye zezimoto ezinamandla amakhulu, njengama-ekseli, amasistimu okudlulisa, njll.