Amazinga Okuhlola Okungeyona Insimbi Ye-ISO:

(1) ISO 4967:2013

I-ISO 4967:2013 “Ukunqunywa Kokuqukethwe Okungafakwanga Kwensimbi Ensimbini – Indlela Yokuhlola Ishadi Elijwayelekile Leshadi Elivamile” kungena esikhundleni se-ISO 4967-1998, kodwa okuqukethwe kwakho kube nezinguquko ezincane kuphela, futhi indlela yayo yokuhlola neshadi lokulinganisa akushintshile.Inguqulo yango-1988 yaleli zinga yamukelwe ngokulinganayo yi-GB/T 10561-2005.

(2) ISO 9341-1996

I-TS EN ISO 9341-1996 "Optics and Optical instruments - Ukunqunywa kokungapheleli kokufakiwe kanye nokukhubazeka kwendawo kumalensi okuxhumana angaguquki" kwethula izindlela nezinyathelo zokuthola okufakiwe kanye nokukhubazeka kwendawo kusetshenziswa amalensi okuxhumana angaguquki.Yanqanyulwa ngo-2006 futhi yathathelwa indawo yi-ISO 18369.3:2006 “Optics and Optical instruments – Contact lens – Ingxenye 3: Izindlela Zokuhlola”.

Izindinganiso zokuhlola ukufakwa okungezona ezensimbi zaseMelika:

(1) I-ASTM B796-2014

I-ASTM B796-2014 "Indlela Yokuhlola Yokuqukethwe Okungeyona Insimbi Ehlanganisiwe Ezingxenyeni Ze-Powder Forged", ingena esikhundleni se-ASTM B796-2007, ilungele ukunqunywa kwe-metallographic yamazinga angewona ensimbi ezingxenyeni ezibunjiwe zempushana, ezidinga ukutholwa kwe-porosity engu-100% endaweni ewumgogodla. kwesampula.Uma kukhona izikhala, kunzima ukuhlukanisa ama-pores asele kusukela ekufakweni kwe-oxide.

(2) I-ASTM E45-2013

I-ASTM E45-2013 “Indlela Yokuhlola Yokunquma Okuqukethwe Okufakwa Ensimbini” iyindinganiso yokuhlola ukufakwa okungeyona eyensimbi esetshenziswa kabanzi, ehlanganisa izindlela zokuhlola ezine ze-macroscopic nezindlela zokuhlola ezincane ezinhlanu (ukuhlaziya okwenziwa ngesandla nesithombe) ukuchaza okuqukethwe kokufakwa ensimbi. kanye nendlela yokubika yemiphumela yokuhlolwa.Izindlela ezinhlanu zokuhlola ezincane kakhulu zifaka: Indlela (indlela yenkambu embi kakhulu yokubuka), indlela ye-B (indlela yobude), indlela ye-C (indlela ye-oxide ne-silicate) Indlela ye-D (indlela yokuqukethwe okuphansi kokufakwayo) kanye nendlela ye-E (indlela yokulinganisa i-SAM);I-ASTM E45 isungule uchungechunge lwamamephu ayizethenjwa ajwayelekile (amamephu e-JK namamephu we-SAE) ukuze achaze izici (usayizi, uhlobo, nenani) lokufakiwe okujwayelekile.Imephu ye-SAE ingatholakala enqubweni enconyiwe yokusebenza kwe-J422 kubhukwana le-SAE;I-spectra ye-Method A (insimu yokubuka embi kakhulu), Indlela D (okuqukethwe okufakiwe okuphansi), kanye nendlela E (isilinganiso se-SAM) yathuthukiswa ngokusekelwe ku-spectra ye-JK, kuyilapho i-Method C (izindlela ze-oxide ne-silicate) isebenzisa i-spectra ye-SAE.

(3) I-ASTM E1122-1996

I-ASTM E1122-1996 “Indlela Yokuhlola Ejwayelekile Yokunquma Izinga Lokufakwa Kwe-JK Ngokuhlaziywa Kwesithombe Okuzenzakalelayo” yayekwa ngo-2006 futhi isihlanganiswe ne-ASTM E45-2013 esanda kubuyekezwa, Izindlela A no-D.

(4) I-ASTM E1245-2003 (2008)

I-ASTM E1245-2003 (2008) “Indlela Yokuhlola Ejwayelekile Yokunqunywa Kokufakwa noma Okuqukethwe Kwesakhiwo Sesigaba Sesibili Ezinsimbi Ngokuhlaziywa Kwesithombe Okuzenzakalelayo.”.Ifanele ukusetshenziswa kwendlela yesithombe ezenzakalelayo ukuhlola okuqukethwe kwe-endogenous inclusions kanye nesigaba sesibili se-microstructure ezinsimbi.Ngenxa yokusabalalisa okuhlakazekile nokungabikezeli kokufakwa kwangaphandle, leli zinga alisebenzi ekuhloleni ukufakwa kwangaphandle ensimbi noma kwezinye izinsimbi.

(5) I-ASTM E2142-2008

I-ASTM E2142-2008 "Indlela Yokuhlola Yokuhlola Nokuhlelwa Kwezinto Ezifakiwe Ensimbi Ngokuskena I-Electron Microscopy".Ngokwezinqubo ezichazwe ku-ASTM E45 kanye ne-ASTM E1245, ukuhlolwa kobuningi bokuqukethwe kokufakwa ensimbi kwenziwa kusetshenziswa isibonakhulu se-electron yokuskena;Ukunqunywa kwenani, usayizi, kanye nokusatshalaliswa kwe-morphology kokufakiwe kuhlukaniswa ngokwezindlela zamakhemikhali.

(6) I-ASTM E2283-2008 (2014)

Njengoba kwaziwa, ukwehluleka kwezingxenye zemishini ezifana namagiya nama-bearings kuvame ukubangelwa ukuba khona kwenani elikhulu le-non-metallic oxide inclusions.Ukubhekwa kwe-Microscopic yezingxenye ezihlulekile ngokuvamile kulandelela ubukhona bokufakiwe.Ukubikezelwa kwempilo yokukhathala kwezingxenye ezihlulekile akukwazi ukuhlolwa ngokunengqondo ngamazinga okuhlola afaka njenge-ASTM E45, ASTM E1122, kanye ne-ASTM E1245.I-ASTM E2283-2008 (2014) “Ikhodi Yokuhlaziywa Kwamanani Aphakeme Kakhulu Okufakiwe Okungeyona Insimbi kanye nezinye izici ze-Microstructure kunsimbi” kuvele ngaphansi kwalezi zimo.Leli zinga lidala indlela emisiwe kusetshenziswa ukuhlaziya inani elidlulele, elihlobene nempilo yengxenye kanye nokusabalalisa usayizi wokufakwa.Njenge-ASTM E1245-2003 (2008), leli zinga alisebenzi ekuhlolweni kokufakwa kwangaphandle kwensimbi nezinye izinsimbi.

Amazinga wokuhlola ukufakwa okungeyona eyensimbi yaseJalimane:

(1) I-DIN 50602-1985

I-DIN 50602-1985 "Indlela yokuhlola i-Microscopic yokuhlola okuqukethwe okungeyona insimbi ensimbi yekhwalithi ephezulu kusetshenziswa imidwebo ye-metallographic" isetshenziswa kabanzi njengendlela yokuhlola i-microscopic yokuqukethwe okungeyona insimbi okufakwe kunsimbi yekhwalithi ephezulu, okubhekiselwa kuyo ngabangaphezu kuka-120. amazinga omkhiqizo.Leli zinga lihlukanisa okufakiwe okungeyona okwensimbi ensimbi ngezigaba ezine: uhlobo lwe-SS, uhlobo lwe-OA, uhlobo lwe-OS, nohlobo lwe-OG, oluhambisana nokufaka i-sulfide, ukufakwa kwe-oxide, okufakiwe kwe-silicate, kanye ne-spherical oxide inclusions, ngokulandelana.Lezi zinhlobo ezi-4 zokufakwayo zihlukaniswe ngamaleveli ayi-9, amelwe ngu-0-8.Amaleveli aseduze abangela umehluko ophindwe kabili endaweni yokufakwa.Ubuningi besampula yisithando somlilo esisodwa noma iqoqo lezinto zokwakha, futhi ngokuvamile awekho amasampula angekho ngaphansi kuka-6.Amagrafu amathathu asetshenziselwa ukuhlola izinga lokufakiwe.Ezingeni elifanayo, i-sulfide inclusions (uhlobo lwe-SS) kanye ne-spherical oxide inclusions (uhlobo lwe-OG) zihlukaniswa zibe uchungechunge olubili ngokusekelwe ekwehlukeni kobubanzi bokufakwa nobukhulu, kuyilapho ama-oxide inclusions (uhlobo lwe-OA) kanye ne-silicate inclusions (uhlobo lwe-OS) zihlukaniswa zibe ezintathu eziwuchungechunge.Ohlotsheni ngalunye lokufakwa kanye nochungechunge ngalunye, ububanzi obuhambisanayo bokufakwa bunikezwa, futhi ithebula lebanga lobude elihambisana nokufakwa kobubanzi obuhlukene nalo linikezwa.Kunezindlela ezimbili zokuhlola ze-DIN 50602-1985: Indlela ye-M kanye nendlela ye-K.Indlela ye-M iwukurekhoda izinga eliphakeme kakhulu lokufakwayo kuyo yonke indawo ehloliwe, futhi ngemva kokuhlola ngokuhlukana nokurekhoda ukufakwa okuhlukahlukene kusampula ekhethiwe, ubale incazelo ye-arithmetic.Indlela ye-K ibala okufakiwe kusuka ezingeni elicacisiwe, ngakho izinga lisebenza ngokuqondile ezinsimbi ezikhethekile.Ngakho-ke, izinga eliphansi lokuhlola lincike kunqubo yokuncibilikisa insimbi, ukusetshenziswa kwezinto ezibonakalayo, nosayizi womkhiqizo.Inombolo engemva kuka-K imelela inani eliphansi lamazinga asetshenziswe ekuhloleni kusetshenziswa igrafu.Isibonelo, i-K4 isho imvamisa yokwenzeka kwamazinga okufakwa kusukela kuzinga lesi-4. Izinga lokuhlanganisa liyahlukahluka, futhi ama-coefficients awo engozi nawo ayahluka.Ukuphindaphinda imvamisa nge-coefficient kukhiqiza inani eliphelele lokufakiwe kusampula eyodwa.Isamba senani lokufakwa kuwo wonke amasampuli eqenjini lesampula liyengezwa, futhi umphumela uguqulelwa ku-1000 mm2, okuyinkomba ephelele yokufakiwe.I-K4 ivame ukusetshenziswa, futhi lapho kubalwa, ukufakwa kohlobo lwe-OS ngokuvamile kuhlukaniswa njenge-OA.Njengamanje, leli zinga alisebenzi futhi alikho izinga elisha elibuyekeziwe elizofakwa esikhundleni salo.Ikomidi layo lezobuchwepheshe lincoma ukuthi kusetshenziswe i-DIN EN 10247-2007 ukuze kuhlolwe okuqukethwe okungafakwa kwensimbi ensimbi.

(2) I-DIN EN 10247-2007

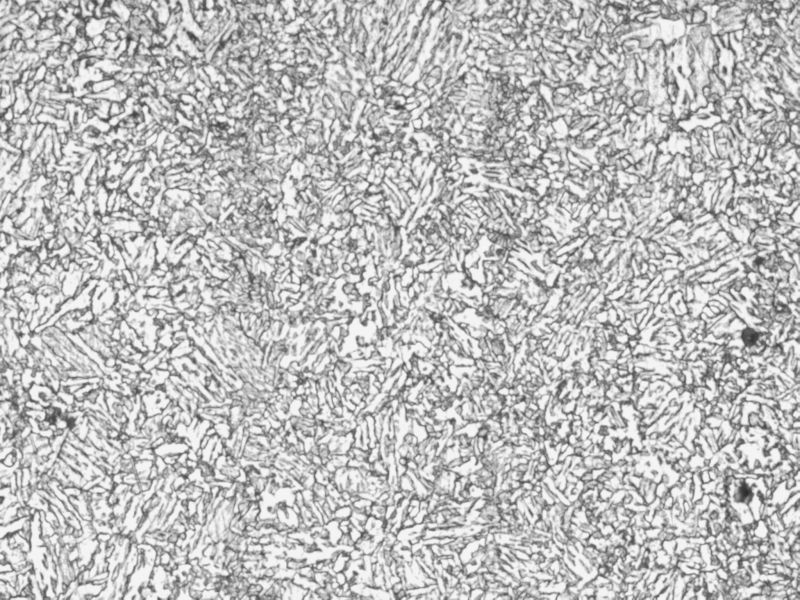

I-DIN EN 10247-2007 “Ukuhlolwa kwe-Microscopic kokuqukethwe okungezona ezensimbi ensimbi kusetshenziswa izithombe ezijwayelekile” kuyindinganiso yendlela yokuhlola i-metallographic yokuqukethwe okungeyona insimbi okufakwe ensimbi ethuthukiswe ngokusekelwe enguqulweni yesilingo ye-DIN V ENV 10247-1998 “Ukuhlolwa kwe-Microscopic kokuqukethwe okungeyona insimbi ensimbi kusetshenziswa izithombe ezijwayelekile”.Leli zinga lihlukanisa ukufakwa okungeyona okwensimbi ensimbi zibe izinhlobo eziyisithupha eziyisisekelo, ezimelwe yi-EA, EB, EC, ED, EF, kanye ne-AD, Izindlela zokuhlola zihlukaniswe ngendlela engu-P (indlela yokufaka embi kakhulu), indlela ye-M (insimu yokubuka embi kakhulu indlela), kanye nendlela ye-K (indawo emaphakathi yendlela yokubuka), phakathi kwayo indlela engu-M kanye nendlela ye-K ihambisana ne-DIN 50602

Incazelo ngo-1985 iyahambisana, futhi amazinga amaningi omkhiqizo asanda kwakhiwa e-Europe aseqalile ukubhekisela kuleli zinga.

(3) Okunye

Amazinga okuhlola ahlobene nokuhlolwa kokufakwa okungezona ezensimbi futhi ahlanganisa: SEP 1570-1971 “Indlela Yokuhlola I-Microscopic Yokufakwa Kwamashadi Okuqukethwe Okungeyona Insimbi Yensimbi Ekhethekile”, SEP 1570-1971 (Isithasiselo) “Indlela Yokuhlola I-Microscopic Yokufakwa Okungeyona Insimbi Amashadi Esilinganiselwa Sokuqukethwe Ensimbi Enhle Nemide Ekhethekile”, kanye ne-SEP 1572-1971 “Indlela Yokuhlola Okuncane Kakhulu Yamashadi Esilinganiselwa Sokuqukethwe Kwe-Sulfidi Ensimbi Yamahhala Yokusika”

Izindinganiso zokuhlola zokufakwa okungezona ezensimbi kwamanye amazwe:

I-JIS G 0555:2003 "Indlela yokuhlola ye-Microscopic yokufakwa okungeyona insimbi kunsimbi" (izinga lesi-Japanese).

Kuyindlela evamile yokuhlola i-microscopic yokunquma ukufakwa okungeyona insimbi emikhiqizweni yensimbi egoqiwe noma efojiwe (enesilinganiso sokuminyanisa okungenani esingu-3).Izindlela zokuhlola zangempela zokufakwa kuleli zinga zihlukaniswe zaba indlela engu-A, indlela engu-B, kanye nendlela yokubala iphuzu elincane lokuhlola indlela yokuhlola.Indlela engu-A kanye nendlela engu-B ihambisana ngokuphelele nendlela yokumelela ku-ISO 4967:2013, futhi indlela yokubala amaphuzu imelela ukuhlanzeka kwensimbi ngamaphesenti endawo ehlala izinto ezifakiwe.Leli zinga lisetshenziswa kabanzi ukuhlola ukufaneleka kwensimbi ukuze isetshenziswe, kodwa ngenxa yethonya elizimele labahloli, kunzima ukuzuza imiphumela egculisayo, ngakho inani elikhulu lamasampuli nokubikezela kuyadingeka ukuze kusetshenziswe.

I-BS 7926-1998 (R2014) “Indlela ye-quantitative micrographic yokunquma iphesenti lokuqukethwe okungeyona insimbi kunsimbi” (Izinga laseBrithani),

Izindlela ezimbili zokuthatha izithombe ezincane zokunquma okuqukethwe okungeyona insimbi ensimbi ekhonjiwe zichazwe ngokuningiliziwe.Ingxenyana yendawo yokufaka okungeyona eyensimbi kumasampula ensimbi ekhonjiwe yacaciswa, futhi ububanzi bamaphesenti okufakwa okungeyona insimbi ezindleleni ezine zokuncibilika nokucwengisiswa ezisetshenziswa izisekelo zensimbi nazo zacaciswa.

I-Gapower Metal entshaungumkhiqizi wensimbi wokusika wamahhala.Imikhiqizo eyinhloko ihlanganisa 1212 1213 1214 1215 1140 1144 12l13 12l14,12l15 11SMn30 njll. Amakhasimende angathola lonke uhlobo lweshubhu abeludinga.

Isikhathi sokuthumela: Dec-25-2023