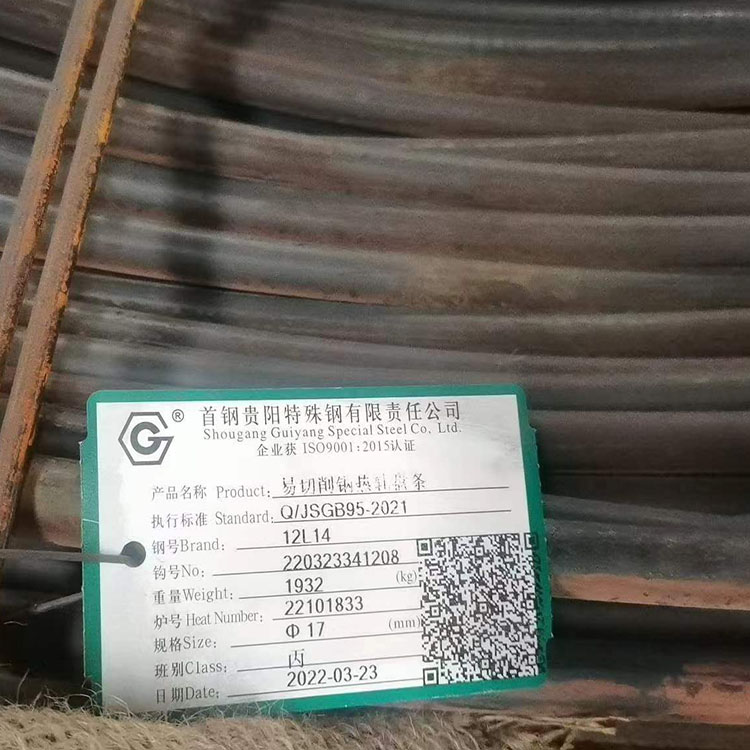

Umkhiqizi we-SAE 1215 / AISI 1215 Cold Drawn Free Cutting Steel Round Bars

Ibhizinisi lethu ligcizelela ngaso sonke isikhathi inqubomgomo yekhwalithi “yekhwalithi ephezulu yomkhiqizo isisekelo sokusinda kwenhlangano;ukwanelisa ikhasimende kuzoba indawo okubhekwe kuyo kanye nesiphetho senkampani;ukuthuthuka okuqhubekayo kuwukufuna kwaphakade abasebenzi” kanye nenjongo engaguquki “yokuba nesithunzi kuqala, umthengi kuqala” kuMkhiqizi we-SAE 1215 / AISI 1215 Ama-Cold Drawn Free Cutting Steel Round Bars, Ngoba sihlala kulo mugqa cishe iminyaka eyi-10.Sithole ukwesekwa kwabahlinzeki abahamba phambili ngekhwalithi namanani.Futhi besinabahlinzeki bempahla abanekhwalithi ephansi.Manje izimboni eziningi ze-OEM zibambisane nathi futhi.

Ibhizinisi lethu ligcizelela ngaso sonke isikhathi inqubomgomo yekhwalithi “yekhwalithi ephezulu yomkhiqizo isisekelo sokusinda kwenhlangano;ukwanelisa ikhasimende kuzoba indawo okubhekwe kuyo kanye nesiphetho senkampani;ukuthuthuka okuqhubekayo kuwukufuna kwaphakade abasebenzi” kanye nenjongo engaguquki “yokuba nesithunzi kuqala, umthengi kuqala”Ibha yensimbi engu-1215, i-aisi1215 ebandayo edonswe ibha yokusika eyindilinga yamahhala, sinomugqa wokukhiqiza ophelele, ulayini wokuhlanganisa, uhlelo lokulawula ikhwalithi, futhi okubaluleke kakhulu, sinobuchwepheshe obuningi bamalungelo obunikazi kanye nethimba elinolwazi lobuchwepheshe nokukhiqiza, ithimba lensiza yokuthengisa yochwepheshe.Ngazo zonke lezi zinzuzo, sizodala "umkhiqizo ohlonishwayo wamazwe ngamazwe we-nylon monofilaments", futhi sisakaze izimpahla zethu kuwo wonke amagumbi omhlaba.Besilokhu sihamba futhi sizama konke okusemandleni ethu ukusiza amakhasimende ethu.

Imininingwane Yomkhiqizo

I-ASTM AISI 1212 1215 1140 1144 Ibha yensimbi yokusika yamahhala iyinsimbi yokusika yamahhala yesibabule ephakathi nendawo ephansi, enokusebenza okungcono kokusika uma kuqhathaniswa nensimbi engu-10# 25# 35# 45#, ASTM 1212 1215 1140 1144 izikhathi, ukwandisa umkhiqizo ngo-30%, futhi unamandla aphezulu nobulukhuni.

Okujwayelekile: ASTM A29/A29M-04

I-ASTM AISI 1212 1215 1140 1144 Insimbi yokusika yamahhala iyimpahla yensimbi enokumelana nokugqokwa okuhle kanye nokumelana nomthelela.Insimbi yokusika yamahhala ivame ukusetshenziswa ekukhiqizeni izingxenye, amathuluzi, noma ezinye izinto zokusebenza, njengezinsimbi zomshini, izinsimbi zomzimba we-valve, njll. I-ASTM1212 1215 1140 1144 insimbi yokusika yamahhala inokumelana nokuguga okuhle kakhulu, ukumelana nokugqwala, nokumelana ne-oxidation, ngakho-ke ingasetshenziswa kabanzi emikhakheni ehlukahlukene yokucubungula imishini.I-ASTM1212 1215 1140 1144 insimbi yokusika yamahhala ibonisa ukumelana nokugqoka okuhle kakhulu emazingeni okushisa aphezulu, kuyilapho emazingeni okushisa aphansi ikhombisa amandla amahle okucindezela nawokuphuma ngaphandle.Ngaphezu kwalokho, insimbi iphinde ibe namandla aphezulu kakhulu futhi ingakwazi ukumelana nemithwalo esindayo.I-ASTM1212 1215 1140 1144 insimbi yokusika yamahhala inokumelana nokushisa okuhle kakhulu futhi ngeke ishise ngisho noma ishiswa amalangabi.

Amapharamitha

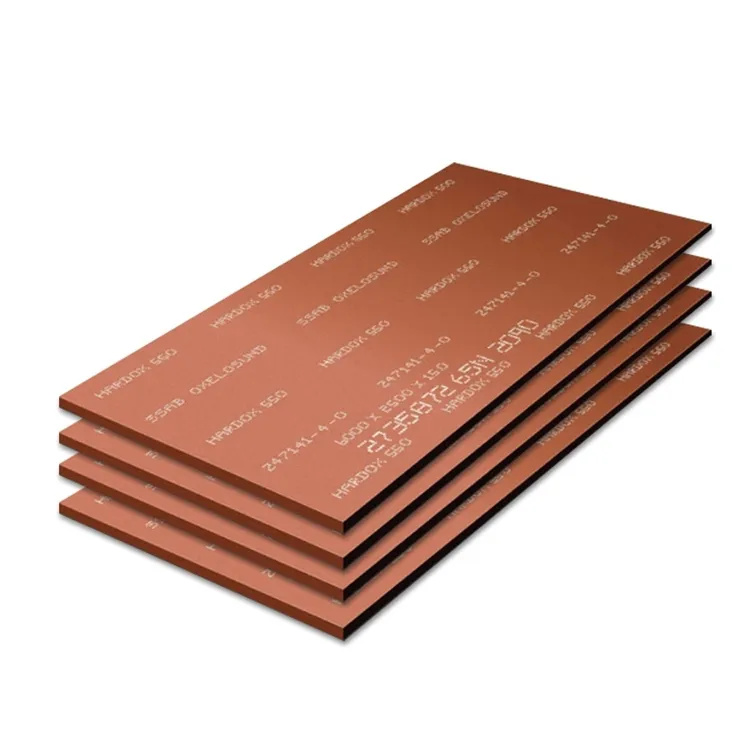

| Usayizi | Ibha Eyindilinga | Ububanzi - 6-1200 mm |

| Ipuleti/Ifulethi/Ibhulokhi | Ubukhulu: 6mm-500mm | |

| Ububanzi: 20mm-1000mm | ||

| Ukwelashwa kokushisa | Okujwayelekile ;I-Annealed;Icishiwe ;Uthukuthele | |

| Uhlobo | Ukudonswa okubandayo/okugoqiwe okushisayo | |

| Isimo sobuso | Mnyama;Ihlutshiwe;Ipholishiwe;Okwenziwe ngomshini;Kugaywe;Iphendukile;Igayiwe | |

| Isimo sokudiliva | Kwakhiwe;Ukushisa okugoqiwe;Kuyabanda | |

| Hlola | Amandla aqinile, amandla okukhiqiza, ukwelula, indawo yokunciphisa, inani lomthelela, ubulukhuni, usayizi wokusanhlamvu, ukuhlolwa kwe-ultrasonic, ukuhlolwa kwe-US, ukuhlolwa kwezinhlayiyana kazibuthe, njll. | |

| Isicelo | I-ASTM 1212 1215 1140 1144 ilungele izingxenye zomshini ezidinga ukuqina okuphezulu, njengesikulufu sokuhola, induku epholishiwe, irack kanye ne-spline shaft, njll. | |

| Ukwakhiwa Kwekhemikhali (%) | ||||

| Ibanga | C | Mn | P | S |

| 1212 | ≤0.13 | 0.70-1.00 | 0.07-0.12 | 0.16-0.23 |

| 1215 | ≤0.09 | 0.75-1.05 | 0.04-0.09 | 0.24-0.33 |

| 1140 | 0.37-0.44 | 0.7-1.0 | ≤0.04 | 0.08-0.13 |

| 1144 | 0.40-0.48 | 1.35-1.65 | ≤0.04 | 0.24-0.33 |

| Amazinga alinganayo ahlukene | ||||

| AISI/ASTM | GB | EN10087 | I-JIS | I-DIN |

| 1212 | Y12 | - | I-SUM21 | - |

| 1215 | Y15 | 11SMn30 | - | - |

| 1140 | Y35 | - | I-SUM41 | - |

| 1144 | Y40Mn | 38SMn28 | I-SUM43 | 44Mn28 |

Iphakheji&Shipping

Ukuqinisekisa ikhwalithi

1.Iqinile ngokwezimfuneko

2.Isampula: Isampula iyatholakala.

3. Izivivinyo: Ukuhlolwa kwesifutho sikasawoti / Ukuhlolwa kwe-Tensile / Ukuhlolwa kwe-Eddy yamanje / Ukwakheka kwamakhemikhali ngokwesicelo samakhasimende

4.Isitifiketi: IATF16949, ISO9001, SGS njll.

5. EN 10204 3.1 Isitifiketi

I-SAE / AISI 1215 ibha yensimbi yokusika yamahhala iwuhlobo lwensimbi yokusika kalula enokusebenza okuhle kwemishini, esetshenziswa kabanzi ezingxenyeni zemishini, imishayo, izinsimbi nezinye izinkambu.

Izingxenye eziyinhloko zensimbi yokusika yamahhala engu-1215 yikhabhoni, i-manganese, nesulfure, enokuqukethwe okuphezulu kwesibabule, okungathuthukisa ukusebenza kokusika kwensimbi.Ukuqina kwensimbi eyi-1215 kuzungeze i-135-180HBW, inamandla okwenza kahle kanye nendawo ebushelelezi eyenziwe ngomshini.Amandla adonsela phansi ensimbi angu-1215 angu-7.85g/cm ³, afana nensimbi evamile.

Insimbi ye-1215 isetshenziselwa ikakhulukazi izingxenye zokukhiqiza kanye nezingxenye, njengama-bolts, amantongomane, izikhonkwane, njll Ngenxa yokulula kwayo ukucubungula nokusebenza kahle kokukhiqiza okuphezulu, insimbi ye-1215 isetshenziswa kabanzi ekukhiqizeni okuningi.Ngaphezu kwalokho, insimbi engu-1215 ingasetshenziswa futhi ukwenza izingxenye zemishini nesakhiwo esinamandla amakhulu.

Ubuchwepheshe bokucubungula bensimbi ye-1215 ikakhulukazi buhlanganisa izindlela ezimbili: ukwelashwa kokushisa nokucubungula okubandayo.Indlela yokwelapha ukushisa ihlanganisa ukucisha nokushisa, okungathuthukisa ubulukhuni namandla ensimbi.Izindlela zokusebenza ezibandayo zihlanganisa ukwelula, ukugxiviza, ukugunda, njll., okungenza insimbi ibe namandla aphezulu kanye nokuqina.Insimbi engu-1215 nayo inokusebenza okuhle kokushisela futhi ingashiselwa kusetshenziswa izindlela ezifana ne-argon arc welding kanye ne-resistance welding.Ukuze uthole ukwelashwa okungaphezulu, insimbi engu-1215 ingelashwa ngezindlela ezinjengokucosha kanye ne-electroplating ukuze kuthuthukiswe ubushelelezi bendawo nokumelana nokugqwala.

Izinzuzo eziyinhloko zensimbi engu-1215 ziwukucubungula kalula, izindleko eziphansi, amandla aphezulu, nokumelana okuhle kokugqoka, okwenza ifanele ukukhiqizwa ngobuningi.Kodwa-ke, insimbi engu-1215 inokuqukethwe okuphezulu kwesibabule futhi ithambekele ekungeneni kwe-hydrogen.Ngesikhathi esifanayo, ijwayele ukucwiliswa futhi ithambe emazingeni okushisa aphezulu, okwenza ingakufanelekeli ukusetshenziswa ezindaweni ezinzima ezifana namazinga okushisa aphezulu kanye nezingcindezi.