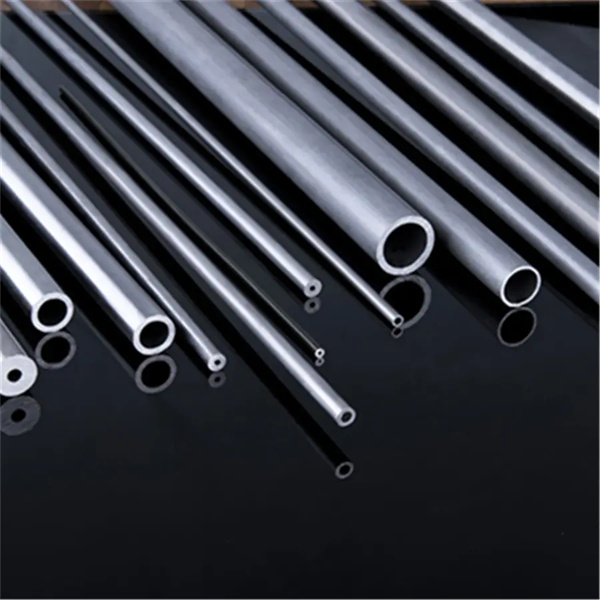

I-AISI4130 ASTM 4130 30CrMo SCM430 ipayipi lensimbi elingenamthungo

I-AISI4130 yaseShayina ibanga lasekhaya elingu-30CrMo insimbi eyingxubevange equkethe i-chromium ne-molybdenum, enamandla aqinile ngokuvamile angaphezu kuka-750MPa.Okuvame ukubonakala emakethe amabha namapuleti awugqinsi.Ipayipi lensimbi elinezindonga ezacile elingu-4130 lizosetshenziswa ukwenza Ibhayisikili noma imoto/uhlaka lwebhasi.Lona umhlangano wepayipi lensimbi elikhiphekayo.Yenziwe ngamapayipi ensimbi angenamthungo adonswa abandayo futhi afakwe ngalinye ngalinye ngokuvumelana nengaphakathi lenqola.

Ipayipi lensimbi elingenamthungo le-AISI 4130 linekhono elihle lomsebenzi, ukuwohloka okuncane kokucubungula, nokumelana nokukhathala okuhle kakhulu.Iyingxenye yensimbi enekhono eliqinile eliphakathi nendawo ukuya phezulu.Ngokwelashwa okufanele kokushisa nakho kwenziwa ngomshini kalula.I-Annealing ASTM 4130 alloy steel inikeza i-ductility enhle kakhulu.Insimbi ye-AISI 4130 ivamise ukunikezwa njengebha eyindilinga ngokuvamile esimweni esiqinile nesithambile.

Ukwakheka Kwamakhemikhali

| Ibanga | C | Si | Mn | P | S | Cr | Mo | Ni |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | 0.035 | 0.04 | 0.8-1.1 | 0.15-0.25 | / |

| 25CrMo4 | 0.22-0.29 | 0.4 | 0.6-0.9 | 0.025 | 0.035 | 0.9-1.2 | 0.15-0.30 | / |

| I-SCM430 | 0.28-0.33 | 0.15-0.35 | 0.6-0.85 | 0.03 | 0.03 | 0.9-1.2 | 0.15-0.30 | / |

Ibanga Lensimbi Elilinganayo

| Izwe | British | USA | Japan | BS |

| Okujwayelekile | BS970 | I-ASTM A29 | I-JIS G4105 | I-EN10083 |

| Ibanga | 708A25/708M25 | 4130 | I-SCM430 | 25CrMo4/1.7218 |

Ukucaciswa

| Qeda Isimo | Ukuphela kwe-beveled, i-plain end, inyamalala, noma ukwengeza amakepisi epulasitiki ukuvikela iziphetho zombili ngokwezidingo zekhasimende | |

| Ubuso Ukwelashwa | Oiled, Galvanized, Phosphate njll | |

| Icebo | Ukudonswa okubandayo nokugoqeka okubandayo | |

| Olunye uhlobo lwamapayipi | 1. Amapayipi ezimoto kanye nemishini | |

| 2. Amapayipi aqhekeka uwoyela | ||

| 3. Ipayipi le-Boiler Elicindezela Kakhulu | ||

| 4. Ipayipi lokuthutha uketshezi olunomfutho ophansi nomaphakathi | ||

| 5. Amapayipi emishini kamanyolo amakhemikhali | ||

| 6. Ukushisa ex-amapayipi okushintsha | ||

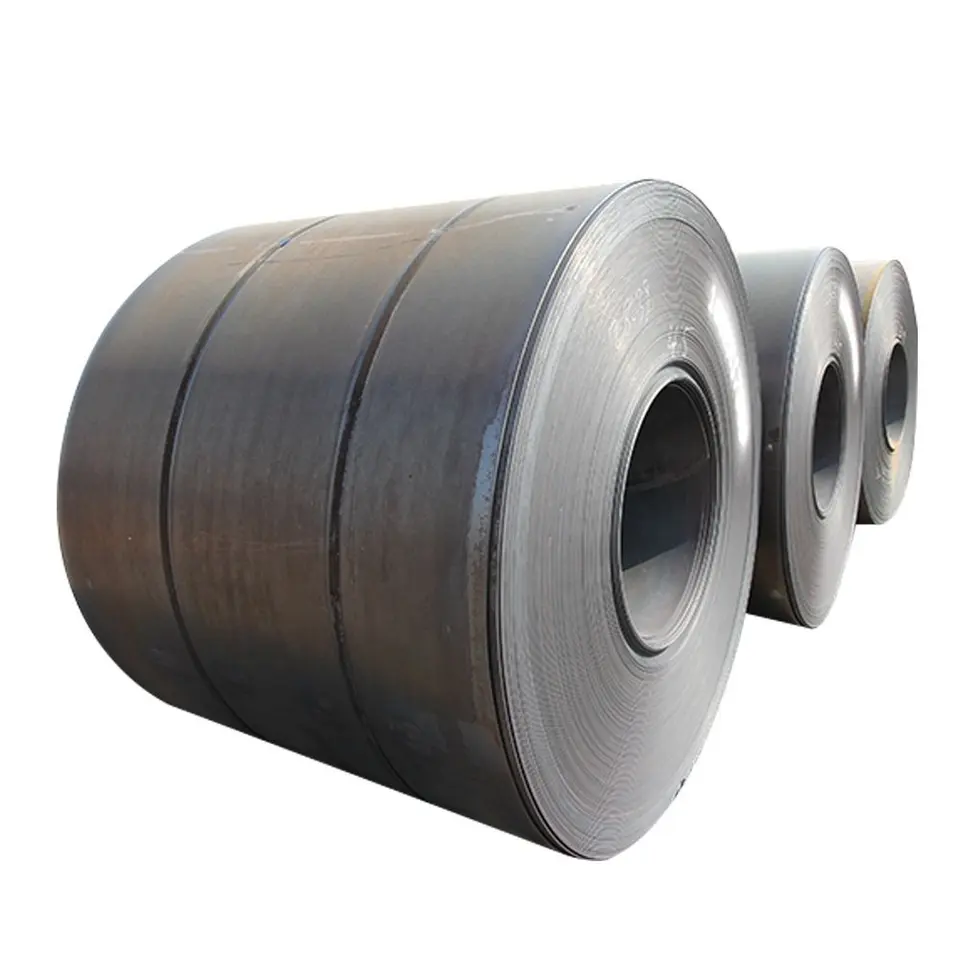

| Ukulethwa Izimo | 1.Njengoba igoqiwe | Ipayipi lensimbi elingenamthungo elishisayo eligoqiwe |

| 2.Amakhaza aginqike | Ipayipi elibandayo eligoqiwe lensimbi elingenamthungo | |

| Iphakheji | 1. Ukupakisha kwenqwaba. | |

| 2. Isiphetho esisobala noma sanyamalala ngokwesicelo sekhasimende. | ||

| 3. Isongwe ngephepha elingangeni manzi. | ||

| 4. Indwangu yesaka enemicu yensimbi eminingana. | ||

| 5. Pakisha emabhokisini asindayo odonga oluthathu. | ||

Amapayipi ensimbi angama-4130 avame ukusetshenziswa ezimeni ezicishiwe nezipholile.Uma okuqukethwe kwekhabhoni kusezingeni eliphansi, insimbi ingasetshenziswa futhi njengensimbi ye-carburized edinga amandla aphezulu aphezulu.Embonini yokukhiqiza imishini esezingeni eliphakathi, isetshenziselwa ikakhulukazi ukukhiqiza izingxenye ezicishiwe nezithambile ezinezingxenye ezinkulu eziphambanayo futhi zisebenza ngaphansi kwezimo ezicindezela kakhulu, njengama-shafts, ama-spindles, namasondo okulawula umthwalo omkhulu, amabhawodi, izigxivizo zekhanda eliphindwe kabili, amagiya. , njll;Isetshenziswa embonini yamakhemikhali ukwenza izingxenye ezishiselwe, izakhiwo ezishiselwe ezakhiwe ngamapuleti namashubhu, kanye namapayipi anomfutho ophezulu osebenza ku-nitrogen ne-hydrogen media emazingeni okushisa angeqi ku-250 ° C;Isetshenziselwa ukukhiqiza ama-turbines nama-boilers, ukwenza izinsimbi ezisebenza ngaphansi kuka-450 ° C, ama-flanges nama-flange covers asebenza ngaphansi kwengcindezi ephezulu engaphansi kuka-500 ° C.

Ukuqinisekisa ikhwalithi

1. Iqinile ngokwamazinga Okukhiqiza.

2. Isampula: Isampula limahhala ukuze lihlolwe.

3. Izivivinyo: Ukuhlolwa kwesifutho sikasawoti / Ukuhlolwa kwe-Tensile / Ukuhlolwa kwe-Eddy yamanje / Ukwakheka kwamakhemikhali ngokwesicelo samakhasimende

4.Isitifiketi: IATF16949, ISO9001, SGS njll.

5.EN 10204 3.1 Isitifiketi