AISI SAE 4130 4140 4145H Steel Round Bar Hollow Rod

Izici

4130 4135 4140 4145H imigoqo yensimbi iyinsimbi ephansi ye-carbon alloy.Zingeze-Chrome-Molly alloy equkethe i-chromium ne-molybdenum njengama-ejenti aqinisayo.

Ibha yensimbi eyindilinga engu-4130 inekhono elihle lomsebenzi, ukuguquguquka okuncane kokucubungula, nokumelana nokukhathala okuhle kakhulu.Iyingxenye yensimbi enekhono eliqinile eliphakathi nendawo ukuya phezulu.Ngemuva kokwelashwa okushisa, i-4140 inamandla amahle kanye nezakhiwo eziphelele zemishini, ikhono elihle lenqubo, kanye nesivuno esikhulu.Izinga lokushisa lesevisi lingu-427 degrees Celsius.

I-4140 inamandla aphezulu, ikhono eliqinile, ukuqina, kanye nokuguqulwa ngesikhathi sokucisha.Inamandla aphezulu okukhasa kanye namandla okubekezela emazingeni okushisa aphezulu.Isetshenziselwa ukukhiqiza ama-forging adinga amandla aphezulu kanye nezingxenye ezinkulu ezicishiwe neziqinile kunensimbi engu-4135, njengamagiya amakhulu okudonsa kwesitimela, amagiya okudlulisa amandla, ama-asi angemuva, izinduku zokuxhuma neziqeshana zasentwasahlobo ezilayishwe kakhulu.

Ukucaciswa

| Igama Lomkhiqizo | AISI ASTM 4130 4135 4140 Ingxubevange Steel Bar | |

| Okubalulekile | I-ASTM | 4130,4135 4140,4145H |

| I-DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Okujwayelekile | I-GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ukuze 600mm | |

| Ubuso | Okupendiwe okumnyama, Okungenalutho, Okupholishiwe, I-Chrome Plated | |

| Imininingwane | Ibha eyindilinga | 8mm ~ 800mm |

| Ibha ye-engeli | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Ibha yesikwele | 4mm*4mm~100mm*100mm | |

| Ibha eyisicaba | 2*10mm~100*500mm | |

| I-Hexagonal | 4mm ~ 800mm | |

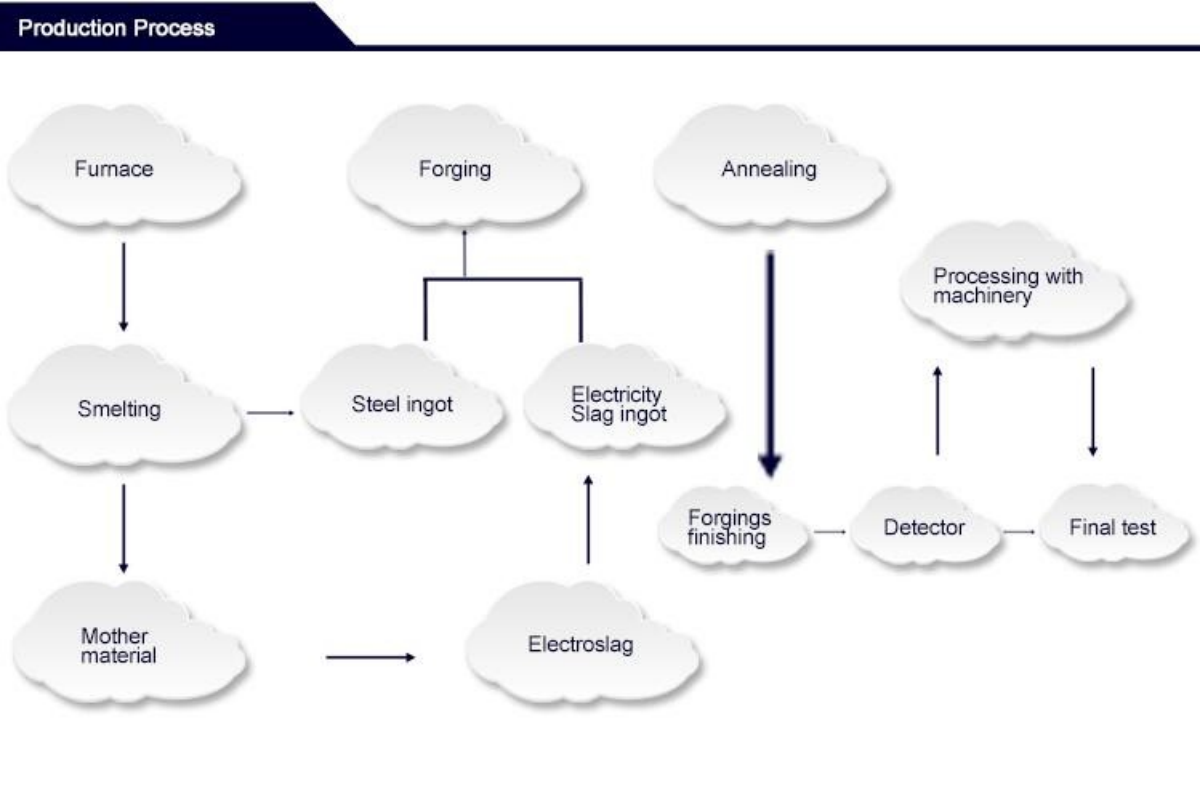

| Inqubo | Isithando somlilo sikagesi sincibilikile, sakhiwe futhi safakwa, ibha eyindilinga ephendukile. | |

| Ukuqina: | I-HBS 217Max (Ihlukile ekwelashweni kokushisa) | |

| Ukuhlolwa kwe-UT | SEP 1921/84/2 C/c ikilasi. | |

| Ukubekezelelana | I-Dia -0/+ 0~5mm, Ukuqina -0/+ 0~5mm, Ububanzi: -0/+ 0~10mm. | |

| Ubude | 2m, 4m, 5.8m, 6m, 11.8m, 12m noma njengoba kudingeka. | |

| Iphakheji | Ukupakisha Okufanele Ulwandle. | |

| Izinga elilinganayo elihlukile | |||

| AISI | GB | I-DIN | I-JIS |

| 4130 | 30CrMo | 1.7218 | I-SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | I-SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | I-SCM432 |

| 4145H | - | - | - |

Ukwakheka Kwamakhemikhali

| Ukwakhiwa Kwekhemikhali (%) | |||||||

| Ibanga | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Izakhiwo Zemishini

| Izici: |

| 1.Insimbi ye-alloy ephansi equkethe i-molybdenum ne-chromium njengama-ejenti aqinisayo; |

| 2.Kuhle kakhulu kumbono we-fusion weldability; |

| 3.I-alloy ingenziwa lukhuni ngokuphathwa ukushisa. |

Ukubekezelelana

| Isimo Sokulethwa |

| 1.Hot rolled |

| 2.Ifakiwe |

| 3.Okujwayelekile |

| 4. Qeda futhi Uthukuthele |

Izimo zokwelashwa kokushisa

1.Annealing: 880℃ Ukupholisa isithando somlilo

2.Ukwejwayelekile: 880~870℃ Ukupholisa komoya

3.Ukuqina: 820~870℃ Ukupholisa amanzi

4.Ukushisa: 550 ~ 650℃ Ukupholisa okusheshayo

Izakhiwo Zemishini zingatholwa ngokwelashwa okuhlukile kokushisa.

Iphakheji

1.Ngezinqwaba, isisindo senqwaba ngayinye singaphansi kwamathani ama-3, kokuncane kwangaphandle

Ibha eyindilinga enobubanzi, inyanda ngayinye enemicu yensimbi engu-4 - 8.

Isiqukathi esingamamitha angu-2.20 siqukethe ubukhulu, ubude obungaphansi kuka-6000mm

Isiqukathi esingamamitha angu-3.40 siqukethe ubukhulu, ubude obungaphansi kuka-12000mm

4.Ngomkhumbi omningi, Inkokhelo Yempahla iphansi ngempahla eyinqwaba, futhi inkulu

osayizi abasindayo abakwazi ukulayishwa ezitsheni zokuhambisa ngempahla enkulu

Ukuqinisekisa ikhwalithi

1.Iqinile ngokwezimfuneko

2. Isampula: Isampula iyatholakala.

3. Izivivinyo: Ukuhlolwa kwesifutho sikasawoti / Ukuhlolwa kwe-Tensile / Ukuhlolwa kwe-Eddy yamanje / Ukwakheka kwamakhemikhali ngokwesicelo samakhasimende

4.Isitifiketi: IATF16949, ISO9001, SGS njll.

5. EN 10204 3.1 Isitifiketi